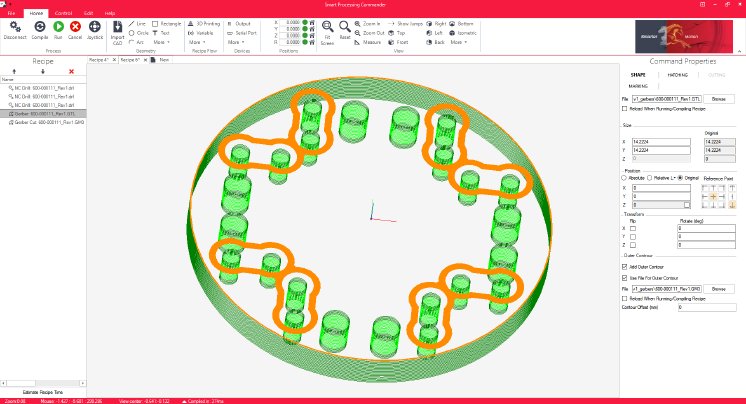

The SPiiPlusSPC software features an easy-to-use, comprehensive interface environment for manual and automated machine operation. Suitable for a wide range of laser processing applications, the application ready SPiiPlusSPC system allows users to create motion/process recipes from one or multiple imported CAD files (DXF, DWG, Gerber, NC Drill, STL, etc.) and/or the built-in geometric functions.

“The SPiiPlusSPC standard software version is a fully functional out-of-the-box solution for complete machine control. The software significantly reduces or eliminates the need for user interface development and maintenance, saving significant programming time and cost,” said Jason Goerges, Product Marketing Manager. “The sophisticated laser control options are synchronized with single and multi-axis motion via our LCMV2 laser control module and drives. This delivers the most accurate laser micro-machining control system on the market.”

Suitable for any PC running Windows 7/8/10, XP with SP3, the SPiiPlusSPC software is optimized to require minimal Windows resources. Customization options are available through ACS and its partners, or via user created plugins.

Applications include 3D engraving, laser micro-processing, polymer processing, laser drilling, PCB drilling, laser cutting, PCB stencil manufacturing, glass and polymer cutting, stent manufacturing, laser additive manufacturing, and more.

For more information on the SPiiPlusSPC software, refer to: https://www.acsmotioncontrol.com/spiiplusspc-

SPiiPlusSPC software data sheet

Contact ACS by e-mail at: sales@acsmotioncontrol.com

About ACS Motion Control

An international manufacturer of advanced multi-axis motion controllers, machine controllers and integrated control modules, ACS provides standard and custom products that combine power and precision to deliver flexible, economical, user-friendly motion and machine control solutions. Established in 1985, ACS’ international headquarters is located in Israel and its North American headquarters resides in Bloomington, MN. ACS also has facilities in Germany, South Korea and China, and distributors worldwide that deliver dependable customer service and product support. ACS is an ISO9001-certified manufacturing facility, demonstrating its continuous commitment to providing customers with reliable devices that are thoroughly tested with the latest available techniques.