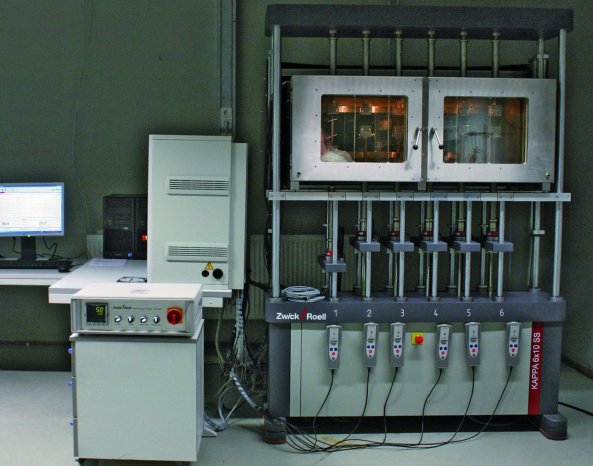

Determining creep behavior has become essential for the development of new materials in the plastics sector. In the testing machine of the University of Bayreuth, up to six specimens can be loaded simultaneously in tensile, compression and 3-point flexure. This allows the change in the material's properties over time to be determined at constant elongation (relaxation) and at constant tension (retardation) as well as under the influence of temperature. Apart from these pure creep test loads, various load profiles can also be applied. At the Department for Polymer Materials, a wide range of materials are tested, such as elastomers, composite materials and thermoplastics.

In order to be able to make a statistically covered statement as quickly as possible, up to six specimens are tested in this testing machine simultaneously. As a standardized test typically last 33 days (1000 hours), this is a decisive advantage. To further shorten the test duration, an attempt is also made to extrapolate the test results to 1000 hours after a shorter time.

The deformation of the specimens is measured contactlessly with a video extensometer, both at room temperature and at an elevated temperature. For this, the testing machine is equipped with a temperature chamber, which enables tests between -50°C and +250°C. With the test software testXpert® II in combination with the measuring, control and regulating electronics testControl, all required test procedures and evaluations can be freely defined.