What are the issues and the benefits of DYNAFORCE input technology?

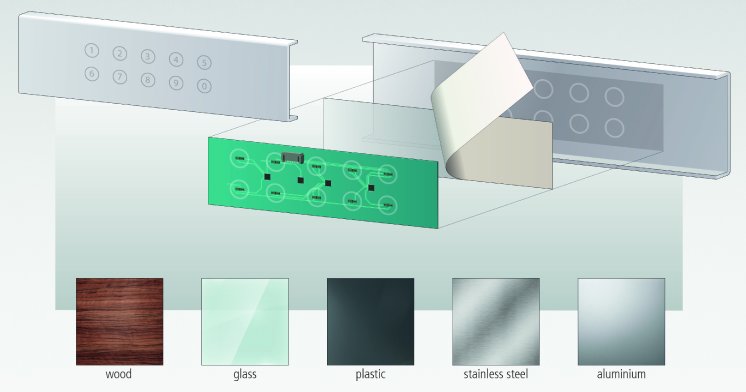

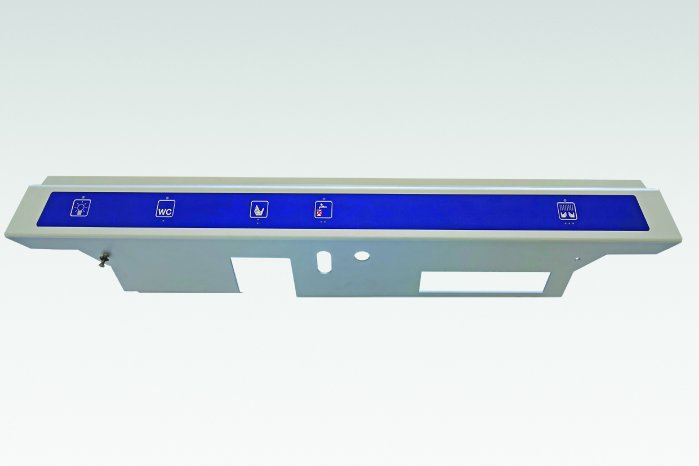

The front panels consist of a closed, weatherproof and water-tight surface made from aluminium, stainless steel, wood, plastic and glass. A user can therefore touch the front panel countless times without any signs of wear. It has no dust-collecting edges. Experience shows that the keyboard can be operated while wearing gloves of all kinds, using pencils etc. – in the food industry, for instance, with butcher's gloves. The product can be fully operated when wet, is protected against vandalism and meets the highest hygiene requirements. The absence of moving parts that result in wear and tear ensures long service life. The key arrangement is freely selectable, taking into account the minimum spacing. The assembly is extremely easy: The internally developed IC module with the electronics (specific ultra-sensitive touch sensors) is simply affixed to the back of the front panel using self-adhesive tape. The tactile properties of DYNAFORCE are reminiscent of a touchscreen monitor as found on smartphones, tablets, etc., with DYNAFORCE sensors measuring the finest surface deformation when the buttons are touched. In order to receive haptic feedback, DYNAFORCE sensors are combined with vibration motors that make them vibrate as soon as the button is pressed. This is the case, for example, with the home button on smartphones and with individual features.

DYNAFORCE demo and developer kit as an excellent start-up aid

According to the manufacturer, anyone who has a genuine keyboard project almost always buys the demo and developer kit. CHF 500 are definitely money well spent for it. The case contains a USB stick with instructions as well as the Demo Software Design-Studio (Windows) developed by the manufacturer. A demo module with visual, acoustic and tactile feedback and three identical 4-button DYNAFORCE modules with VHB tape for self-assembly are also included. A 3N actuator for calibrating the buttons, a stamp for pressing the printed circuit boards in the sensor area, and all the necessary connecting and adapter cables top it all off. This means that the new customer can get started straight away.

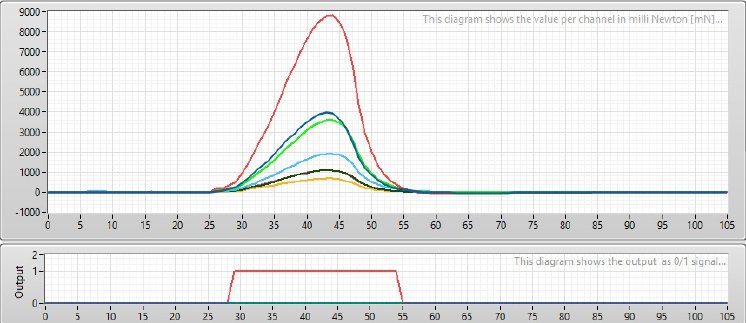

The ultra-sensitive touch sensor (based on the strain gauge technology) is used for measuring pressure. Various pressure strength characteristics (in mN) are graphically displayed in analogue and digital form by the software design studio on the PC. The key that is pressed in each case indicates the highest value in the graphic and the ratio to other measured values should be correctly set.

Based on prior experience, who are the DYNAFORCE customers?

The customer portfolio is very diversified. DYNAFORCE equipment is used in the areas that set high standards for vandalism protection, hygiene and design. This is especially true for ticket machines, parking ticket keyboards, sanitary facilities, and trains. These also need to be water-proof and robust when installed in public bathrooms and sanitary units. Design aspects are also in demand: our customers often choose metal touch input technology made of stainless steel or aluminium, for aesthetic reasons. Medical and laboratory equipment must be operated in gloves to ensure compliance with hygiene requirements. And DYNAFORCE is a force touch: The key input can be designed depending on the press-on force. This opens up numerous, innovative functionalities for developers. An impressive international reference list proves the success of the DYNAFORCE technology.