- Survey of German industrial managers on success factors of innovative companies

- Systematic use of external knowledge ranked lowest

- Only seven percent of companies consistently incorporate external expertise into their innovation processes

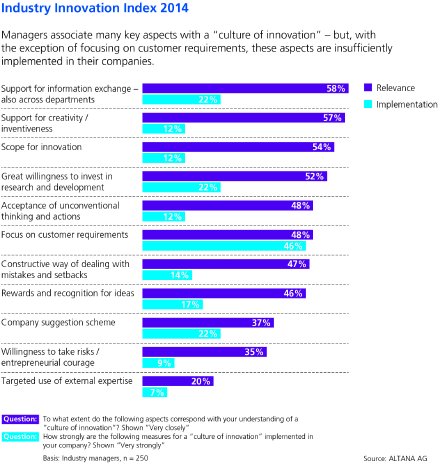

Globalization and short product life cycles are increasing the pressure on companies to open up their innovation processes. However, currently German industrial managers rate the use of external knowledge as least relevant for successful innovation. Only seven percent make a conscious effort to build and maintain networks with specialists. These are the results of the new Industry Innovation Index, for which the market research institute Forsa polled 250 top decision-makers across all sectors and 250 entry-level employees in German industrial companies, on behalf of the specialty chemicals Group ALTANA.

At present companies are primarily focusing on internal programs. For one in two managers, the key features of innovative companies are the promotion of exchange between departments (58 percent), creativity and inventiveness of employees (57 percent), and scope for innovation (54 percent).

ALTANA believes that in the medium term there is no way to avoid opening up innovation processes to outsiders. Dr. Matthias L. Wolfgruber, CEO, is convinced, "Going solo in the area of research and development does not lead to optimal results. Innovation management in conjunction with other companies, customers and suppliers not only helps to minimize the risk of poor investments, but also opens up brand new opportunities."

A process of rethinking is on the horizon within companies. In 13 percent of companies with more than 1,000 employees, external knowledge is already incorporated into the innovation processes in a systematic way.

Use of external knowledge requires a functioning internal information management system

For many smaller companies, opening up innovation processes is too complex. "Thanks to the Internet a sheer unlimited amount of information is available almost like an additional raw material. But it is all about using the right sources of this raw material quicker than the others, and gaining valid insights and knowledge," adds Dr. Georg F. L. Wießmeier, Chief Technology Officer, ALTANA AG. "The prerequisite for this is an intact internal information management system and a network of committed staff who devise methods for efficiently researching and selecting external information in order to glean new knowledge for the company."

Background to the Industry Innovation Index study

The Industry Innovation Index illustrates the state of innovative capability and the culture of innovation in German industrial companies. In November and December 2013, the market research institute Forsa carried out 500 telephone interviews with representatives of industrial companies with a staff of 250 employees or more, on behalf of the ALTANA Group. A total of 250 members of management boards, managing directors and division heads were interviewed. At the same time, Forsa polled 250 entry-level employees at industrial companies aged between 18 and 35, with work experience of between two and five years.

The Industry Innovation Index developed as part of this study shows the relationship between companies perceived as being innovative and those that are not. An index value of more than 100 means the innovative capability is perceived as being positive in this branch of industry.