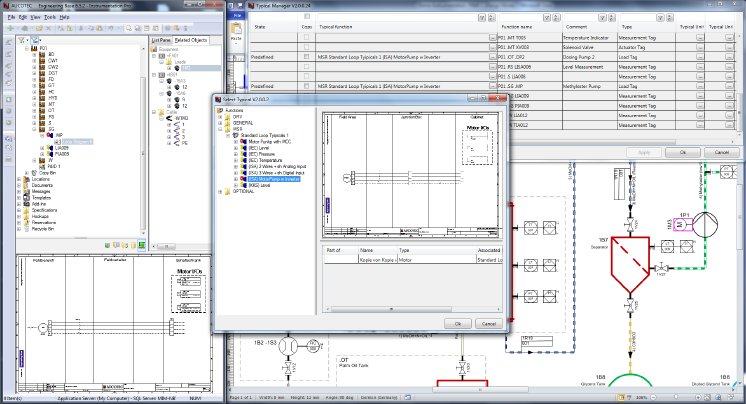

Function modules instead of thousands of sheets

The new Typical Manager makes use of functional engineering in order to fully exploit the undoubted savings potential in configuring. The mechatronic modules to be configured no longer consist of individual motors or sensors, but consist instead of complete functions such as gripping or heating. Thus the configuration is located at a level higher than sheet level and is clearer and more precise as a result.

The documentation of such a function consists of a quality-tested template (typical). This typical contains the associated sheets, devices, cables and wires which are handled "as a whole" in their functional context. This saves you from copying a project consisting of thousands of independent single sheets which cannot be continuously maintained. In addition, unavoidable changes which arise while constructing the plant can be incorporated via the update function without having to undo the individual customisations that were already created up to that point. Thus the entire project no longer has to be regenerated in the event of subsequent changes or has to be created "manually" as of the change request. This saves a lot of time.

Documentation at the press of a button

With the Advanced Typical Manager, options such as brakes or sensors are defined separately as circuit components in EB. The otherwise necessary variants of sheets with all possible combinations of options for one motor are thus a thing of the past. In the event of changes, you swap only the optional circuit component instead of "drowning" in variants and options. EB also stores the data as quality-tested modules for variants resulting from different dimensions or manufacturers. When selecting a particular motor, the system automatically assigns the correct item numbers to the correct components. If all functions which can be ordered are preconfigured in the EB database, the Advanced Typical Manager will provide yet another level of configuration: the documentation of the entire plant or machine at the press of a button.

Seamless PLM integration between Teamcenter® and Engineering Base

With the new interface to the PLM system Teamcenter®, which Aucotec will also be introducing live for the first time at Hannover Messe, all information about a plant, machine, or a mobile system can be securely managed throughout its entire life cycle. Thus the management and forwarding of released engineering documents is possible with access control and revision management for rapid availability of all current project data from EB. You can also easily create and update order or production lists to provide correct data at all times to all departments involved. The new solution automatically synchronizes the catalogue information with the article master data. This prevents multiple entries and unnecessary errors. In addition, each workflow can be customised.

The Teamcenter® interface is the result of an agreed collaboration between Aucotec and Siemens PLM solutions 2014. Siemens PLM Software is one of the leading providers of PLM software and services worldwide.

Aucotec at Hannover Messe: Hall 7, stand B 28