IEC 61850 defines the way in which the numerous devices in switching stations for the distribution of electrical energy (substations), such as control and protection devices, are described and how information about these devices is exchanged. EB is the only system to date that supports the standard both in structuring the system and in understanding the neutral Substation Configuration Language (SCL).

Manufacturer-neutral and future-proof

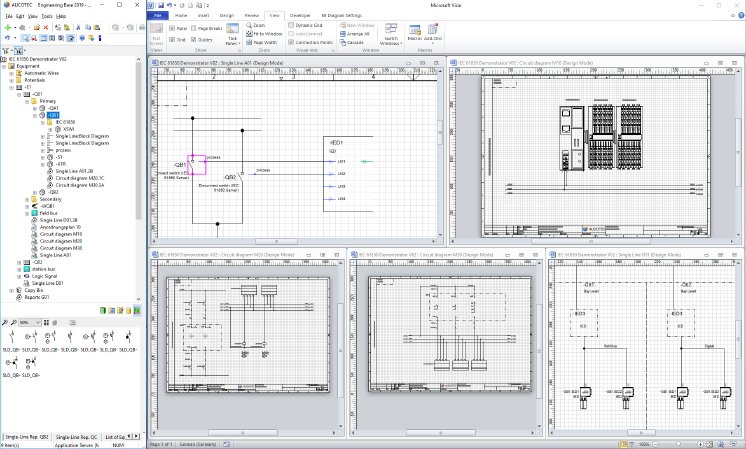

The Substation Configuration Tool (SCT) integrated in EB is the consequent implementation of the IEC 61850 requirement for a manufacturer-neutral configuration tool based on SCL. From the graphic input of the primary technology to the modelling of abstract function nodes and data objects to the linking of the plant model and system components, the SCT generates the target system-independent configuration data for station control systems in conformity with the standards. Furthermore, EB is able to generate a normative SCD file (Substation Configuration Description) that summarises all information about the object model of the plant, from the topology to the network plan. This enables consistent system engineering with future-proof archiving of valuable data in a standardised format.

Object orientation makes it possible

EB's object orientation also keeps the digital twin, the data model of the substation, alive, i.e. up-to-date. It does not "disappear" into folders or document management systems as is usually the case. Each object exists only once in the model; changes are always present across disciplines. "Thanks to the SCT integration, the IEC-61850-capable devices automatically align themselves," says Michaela Imbusch, Product Manager at Aucotec. This ensures a consistent combination of electrical engineering planning and standard-compliant description of the switching station.

No in-depth knowledge necessary

Another special feature: "Thanks to EB's virtualisation of the plant, the logical nodes of the individual devices are created by simply connecting them graphically to the Intelligent Electronic Devices," explains Imbusch. "Therefore, users do not need to have a deeper knowledge of the standard. Because all important information and data on the individual devices are stored in the platform. Here, too, it takes care of everything else for the users.

Thanks to the synchronous coupling of SCT and EB, redundant entries and data maintenance are a thing of the past. In addition, the data for the specification file (.SSD) can be retrieved from EB with SCT and transferred to the IEC 61850-compliant engineering process for plant configuration. This makes the process chain much more consistent, from the overview circuit diagram to the engineering details of the devices. Coordination errors are avoided; this also saves both time and costs.

Aucotec at the Schutz- und Leittechnik event on 21/22 June 2022: Stand 4