The drives in question operated on an infeed conveyor to the shrink-wrapping machine. Motors were controlled by variable frequency drives (VFDs) to deliver an increased performance envelope, with each typically operating between 70 - 80 Hz. To boost production and profitability, the motors' speed was increased via the VFDs to 80 - 90 Hz. The traditional Stainless-steel motors utilized by the manufacturer could not cope with the speed boost in the long term, with the devices producing excessive heat, which eventually caused the motors to fail completely. Clearly, a more efficient and high-performance motor solution was required to improve productivity.

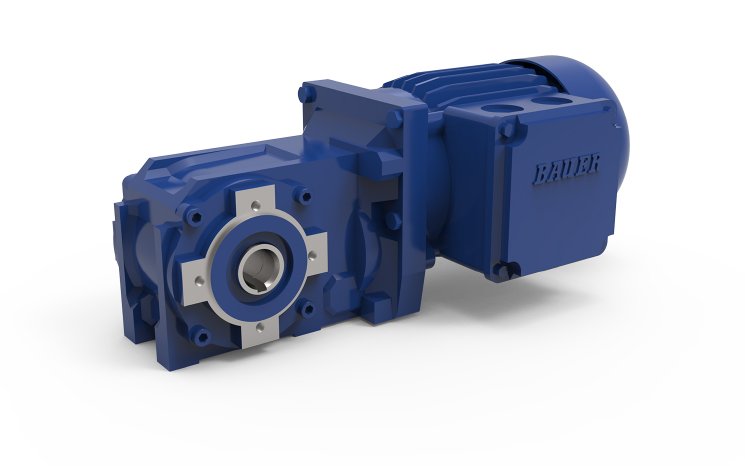

Bauer Gear Motor, a leading brand of the Altra Industrial Motion Corp., has been providing hygienic geared motor solutions to the food and beverage industry for decades. It offers geared motors in ranges right up to IE5 efficiency ratings, according to IEC TS 60034-30-2, so blending high motor performance with market leading efficiency is nothing new for the company. In this particular case, the BK Series geared motor range, widely used in food and beverage processing lines around the world, was deemed a suitable replacement.

The BK06 model specified for the pizza conveyor is a right-angle bevel geared motor, delivering a distinct mechanical efficiency advantage when compared to worm geared alternatives. This increased efficiency is complemented by the fact that the BK06 utilizes a permanent magnet synchronous motor (PMSM), a design which reduces heat losses from the rotor by 100% and total losses by around 25%. Compared to the original equipment, the BK06 can provide up to a 10% improvement in overall efficiency.

One inherent advantage of a PMSM is the capability to provide efficient operation at a wide range of speeds. This benefitted the manufacturer, who was able to increase output speeds to 80 RPM comfortably. The underlying reliability problem was solved, while extra performance was available to operators. The BK Series can be specified with torques ranging from 80 Nm to 18,500 Nm, so is highly versatile in meeting a wide range of operational requirements.

The new BK06 geared motors provided a combination of reliability, efficiency and performance. Maintenance requirements were greatly reduced, resulting in increased uptime. These characteristics also translated to a lower total cost of ownership, with the reduced energy requirements of the BK Series providing a future-proof solution against rising energy costs too.

In addition, the BK Series is inherently compact and offers versatile mounting options, an important feature in the confined areas of a space-efficient food processing line. All motors in the range are sealed, ensuring that dust and moisture cannot compromise the internals of the motor, while also ensuring that the frequent washdowns in the food and beverage industry do not compromise the reliability of the device. A wide range of corrosion protection levels are available to specification, as well as an ingress rating of up to IP66.

For applications such as pizza conveying and packaging, choosing a future-proof motor solution can mean the difference between safeguarding profit or damaging it. However, by selecting a highly efficient, performance-oriented geared motor solution, manufacturers can be sure of reliable production output and maximum profitability.