During its hardware and software development, Baumüller always considers the networking of the machines and systems in a horizontal as well as vertical direction. That is why Baumüller enables web capability, interface variety, service concepts with networking options, etc.

Machines as good as new

Baumüller’s system house, Baumüller Anlagen-Systemtechnik GmbH & Co. KG, has longstanding experience in the areas of retrofitting and reengineering. Trade fair visitors will find out how machines can be made more reliable, durable and productive through modifications, process optimizations, software updates and hardware modernizations. In this process, Baumüller is available as a competent partner from the consultation and implementation to the commissioning and installation. Visitors can get information about standard services such as repairs and maintenance independently of the manufacturer as well as customer-specific packages that are adjusted to individual requirements.

In the service area, Baumüller will also show concepts that reduce downtime with diagnostics and condition monitoring. This presentation highlights techniques and skills that can improve the availability of machines and reduce the cost of servicing and maintenance when they are combined with networked condition monitoring and diagnostics systems. In the form of the patented Baudis solution, Baumüller offers a reliable tool specifically for the printing industry. The automation expert from Nuremberg provides software and hardware solutions to get new and existing machines fit for Industry 4.0.

The Baumüller subsidiary Baumüller Reparaturwerk will present a broad range of services independently of the manufacturer. The service specialist covers all requirements of machine operators and manufacturers with retrofitting, maintenance, repairs and more. Its solutions for networked service enable proactive maintenance with minimal downtime.

The extensive service offer is rounded off by the Baumüller subsidiary Nürmont Installations GmbH & Co. KG, which presents its services in the areas of relocation, installation, logistics and special parts manufacturing.

From the component to the system

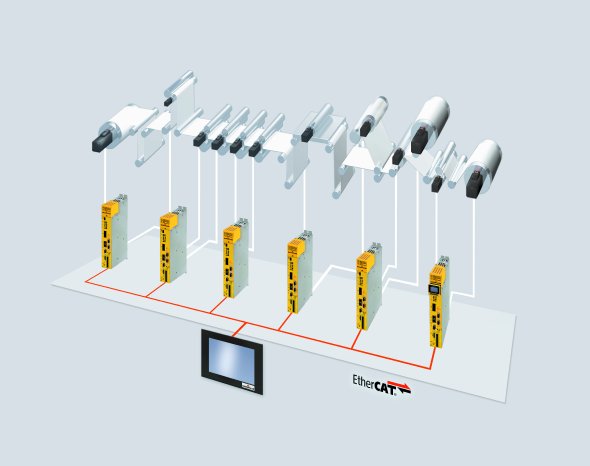

At the Baumüller booth, machine manufacturers have the opportunity to find out about the entire bandwidth of components, systems and solutions for the automation of print and paper machines. Baumüller products offer a great variety of interfaces and fieldbus options that ensure flexible design and enable networked machines. Machine manufacturers can also reduce their time to market and cut costs with the help of extensive software libraries and the ProMaster engineering tool.

The inverter series b maXX 5000 and b maXX 3300 cover axis performances of up to 368 kW and up to 600 kW for parallel connections, fulfilling all requirements for every kind of machine from offset printing to package printing. Stackable devices are available with the convenient drive-connect system, which saves time particularly during the commissioning and servicing through a rapid exchange of individual modules, thereby cutting costs. The portfolio also includes mono devices and multiple axis controllers as well as feeder and regenerative units. Users have the option to select security functions while the softdrivePLC also enables the outsourcing of regulating tasks to the controller at extremely short cycle times of 62.5 µs. Baumüller also has one of the largest selections of motors on the market and offers efficient and scalable servo motors, main drives and high-torque motors in numerous versions and sizes.

With the new family of HMIs and the new Box PCs PCC04, Baumüller offers a high-performance package for control and visualization. The HMIs, which include Windows as well as Linux-based devices, are available in three versions and with display sizes from 4.3 to 15.6 inches. The scalable and flexibly expandable PCC04 has a large amount of interfaces and supplements the HMIs to provide the ideal solution for the control and visualization of printing machines.

Many years of expertise

Baumüller has supported the development of the graphic industry for many decades and has reliable process know-how that goes beyond just the components. This know-how is integrated into the consultations, project planning and creation of software packages. Users can significantly reduce their time to market with the preprogrammed elements and practical tools such as the ProMaster engineering framework.