Baumüller utilizes decades of experience from motor development as well as the production of electric motors and offers energy-efficient components and complete solutions for hybrid and fullyelectric drive systems. The low-noise and low-emissions drive solutions are used, among other things, in hybrid agricultural machines, snow groomers or fully-electric city buses.

Intelligent Drive Solutions

The drive system of a fully-electric municipal vehicle can be seen as an exhibit at the Baumüller trade fair booth. With this solution, two electric drives were mounted to the rear axle of the vehicle. Each drive system consists of a Baumüller DSA synchronous external rotor motor with integrated inverter.

Baumüller also designed and implemented the drives for a loader. The loaders typically driven with combustion engines also operate hydraulic cylinders via the diesel drive, for the bucket for example. For one order, both the traction drive as well as the drive of the hydraulic cylinders were completely converted to be fully electric.

Product Highlights

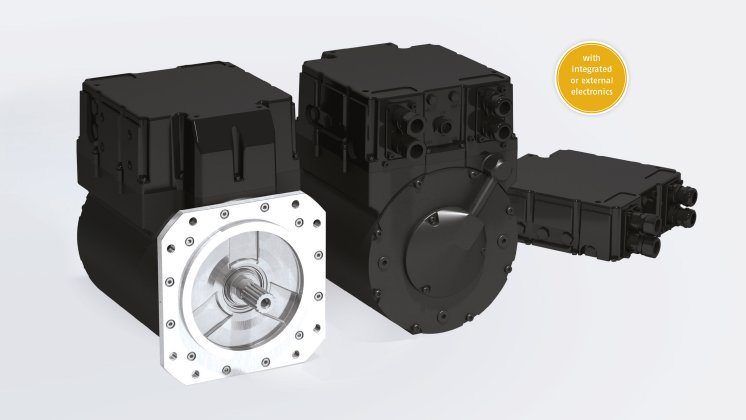

Designed for four-quadrant operation, the b maXX mobil controller can break in both directions and recover energy in addition to generating drive. For mobile use, the controller is vibration resistant and can be used in temperatures between -25 ° and + 65 ° Celsius. For example, the B maXX mobile is suitable for use as a wheel-hub drive with DSM disc motors, which excel thanks to their compact design, highly dynamic running characteristics and low maintenance requirements. Baumüller thus provides a space-saving and high-performance solution.

With its high power density, compact and sturdy design and recuperative ability, the drive concept powerMELA® meets all the requirements of the electric mobile drive technology. The compactness is due to the integration of the inverter on the one hand and the compact design of the electric motor on the other. The motor offers a high power density thanks to its innovative direct cooling concept. The drive system thus requires minimum installation space and only weighs around 300 kg with the motor, inverter and transmission. In addition, Baumüller has designed the permanent magnet synchronous motor with deeply buried magnets. The drive is thus particularly robust on the one hand and powerful on the other with high torques beyond the entire speed range. The motor is available in the performance classes of 40, 80 and 140 kW.

BAUDIS IoT increases availability

BAUDIS IoT is an innovation in the field of mobile working machines. The system optimization tool helps to improve the efficiency of the drives. The networked system consists of sensors, a BAUDIS IoT box and an easy-to-use software with smart data algorithms. BAUDIS IoT monitors the process data of the drive, such as the motor status, power peaks and runtime. The data is collected in the BAUDIS IoT box and passed on to a local server or a cloud server. The performance data is analyzed and visualized there with the BAUDIS IoT software. By using BAUDIS IoT, for example, benchmarks can be set and the electric drive and load cycles can be optimized. The evaluation always occurs with the latest available algorithms. The system is thus continuously made more intelligent and increases performance through self-regulating processes. The system can be used independently of the manufacturer of the motor and automation components and the sensors and therefore can easily be retrofitted and upgraded.