To this day, the paper’s print version remains the core product and economic backbone of Rhein-Zeitung Mittelrhein-Verlag GmbH, Ko-blenz. Even back in 1969, Rhein-Zeitung issued its own editorial stat-utes committing its editors to remain independent from any govern-ment authorities or political parties and to fend off any interference or undue influence.

And while everybody else was still casting a critical eye on the internet, the publishing house, under the umbrella brand of Rhein-Zeitung, ven-tured into this new market back in 1995 without ever looking back – all in an effort to keep its younger readership on board: Mittelrhein-Verlag was the first German Daily paper to establish an online service with its own editorial department. Since 1996, all articles have been accessible on the internet via full-text archives. With the launch of its E Paper in 2001, the publishing company introduced the world’s very first one-to-one issue of a daily paper on the internet. Even faster communication and access to the messages and news essential to producing a newspa-per is ensured by red.web, an internet-based editorial system intro-duced in 2003 by Rhein-Zeitung. Together with other newspaper pub-lishers, Mittelrhein-Verlag has since June 2008 been a partner of kalaydo.de, a huge regional advertising network to which Rhein-Zeitung has transferred its online advertising business.

All New Printing Center in Koblenz

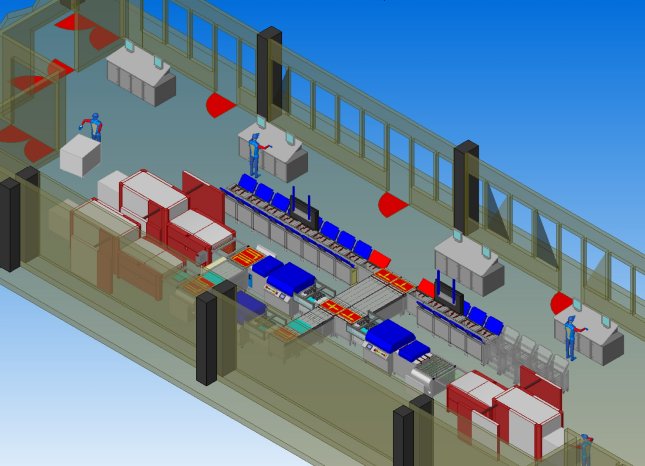

In July 2010, the publishing house decided to procure a KBA Com-mander CT triple-width compact press from Koenig & Bauer (KBA). This 96-pages plant featuring four (4) reel changers, four (4) 6/2 printing towers and two (2) folders is scheduled to start production in the newly built printing center in Koblenz by 2012.

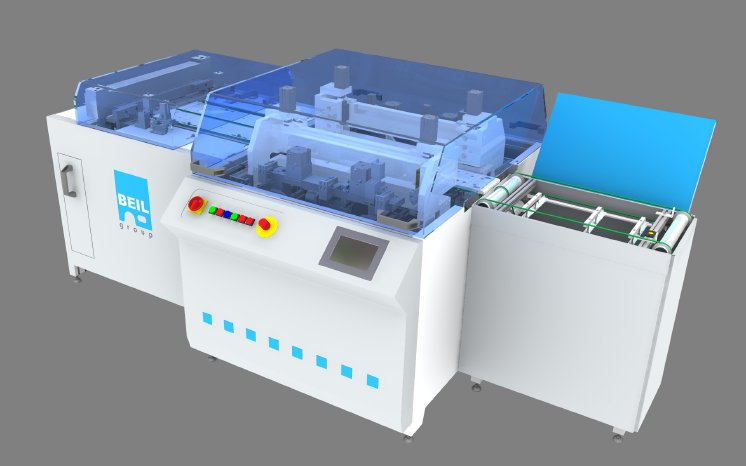

To further upgrade their new printing machine, Rhein-Zeitung recently commissioned a cutting, punching, bending and sorting machine for the printing plates from Beil Registersysteme GmbH, Abensberg. Maxi-mum throughput of this new system is approx. 1,000 plates per hour.

Integrated system solution

For state-of-the-art printing plate logistics, Beil developed a flexible modular system which seamlessly connects to the printing machine manufacturer‘s standard interfaces. As Siegmund Radtke, head of the publishing house, comments: “We picked just the right modules for our plant to best support our workflows and help us fill in the ’automation gap’ between pre-press and printing to the greatest possible extent – and at reasonable cost. And Beil was there for us every step of the way, assisting us with professional planning and sustainable calculation models“.

Up to 1,000 printing plates per hour

The secret behind this extraordinary plate throughput rate in Koblenz is the sophisticated workflow of Beil’s printing-plate machining centers. As a first step, the printing plates are aligned and cut, and subse-quently transferred to a punch bender with video alignment - for ultra-precision positioning of the printing plates at micrometer tolerances. The video alignment results are memorized plate-specifically for later evaluation; faulty plates are discharged. Automated handling sections between the plant’s three processing lines enable redundant operation.

In-plant logistics all the way to the printing tower

Following processing, all plates are forwarded to a dual, fully redundant sorting station for sorting the printing plates by customer-specified criteria and stacking them on a total of 32 transport vehicles. Rotary stations ensure set-down of the printing plates by their leading edges at all times. Additionally, the plant features two express stations which are served preferentially by the Beil PlateTracking Software (BEIL-PTS) to respond promptly to current events or incorrectly exposed plates. The BEIL-PTS software keeps track of the positions of all printing plates at all times and communicates on status level with the ABB PlateWorkflow system.

The sorting station dynamically monitors the transport vehicles to en-sure that stacking of the printing plates will commence only after a transport vehicle has docked to the appropriate position. The transport vehicles carry the printing plates inside plate containers which protect them en route to the print shop – all the way to the lifting platform at the printing unit. The printing plates are unloaded at the printing tower, sorted into the KBA PlateBox magazines, and transferred to the KBA PlateTronic fully automatic plate changer.