By embedding an RFID chip at the very start of the production process you are able to identify and trace your PCBs from the outset, and also protect yourself from counterfeiting. The RFID chip can store information about revision status, firmware, repair and upgrade histories, anti-manipulation measures, along with other customers imagined uses. Data can be retrieved using a reader even if the PCB is no longer visible. In addition, data can be written onto the chip during the product life cycle. The RFID chip information will even make it easy to separate all the production materials for recycling.

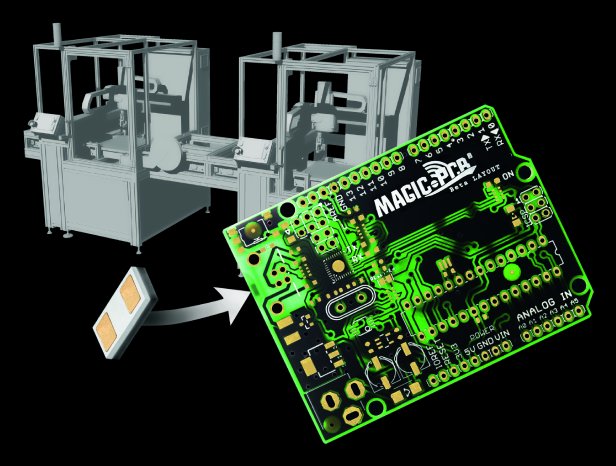

Our patented embedded RFID production process will soon be available under licence so that every PCB manufacturer can take advantage of it. Our partner is Schmoll Maschinen GmbH. PCB manufacturers can order a Magic Application Machine from our partner and use the embedded RFID technology under licence from Beta LAYOUT.

Customers who prefer to start using this technology immediately without investing in their own machine, can try our Beta LAYOUT RFID Service Centre. Just send Beta LAYOUT the production panels you've prepared. We will then create and embed the RFID chips using the MAM machine and deliver the PCBs back to you for the next stage of production. http://www.rfid-service.com/