The importance of CO2 refrigeration systems for subcritical and transcritical applications has risen in recent years and is set to keep rising. However, this growth has been at different speeds in different places, with Northern Europe and Australia taking the lead. BITZER turned its attention to this technology early on – launching products on the market to meet different requirements and constantly developing them. Their market share is growing not only in Europe but also in North America.

Supermarkets equipped with CO2 refrigeration systems

With its product portfolio, BITZER is among the established suppliers in the USA. Five years ago, they commissioned their first subcritical CO2 refrigeration system in a supermarket in Saratoga Springs, New York. The first system to feature transcritical CO2 compressors made by BITZER in the North American market has been up and running in a Canadian shopping mall for more than three years.

This system has been working fault-free ever since it was manufactured, an achievement that requires close cooperation between project partners during the planning, commissioning, and service phases. BITZER provides its partners with its global experience in the use of compressors, and it advises and trains customers in how to use compressors for subcritical and transcritical CO2 applications. In addition to our experts at our headquarters in Germany, application technicians in Canada, the USA, and Mexico are on hand to provide quick and expert assistance on location. Our compressors for subcritical and transcritical CO2 applications have UL certification, and as of this year our SL compressors are also being manufactured in Oakwood, Georgia. Production of compressors for transcritical applications is scheduled to begin there at the end of the year.

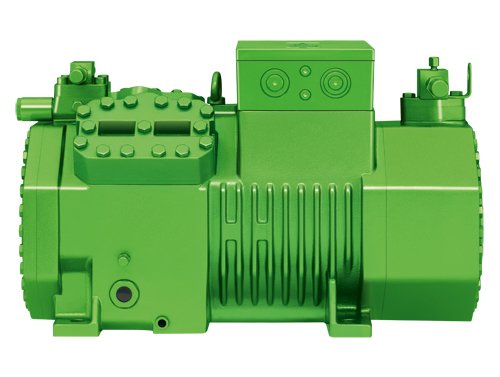

Compressors for subcritical and transcritical CO2 applications have to meet special safety, dependability, and efficiency requirements because of the particular characteristics of CO2 itself. Thermal loads, high operating pressures, and high specific refrigerating capacity combine to produce considerable forces and burdens on smaller components. BITZER has developed new standards over recent years in connection with subcritical and transcritical operation and by meeting requirements in the adaptation of its compressors’ performance.

Aside from being reliable, it also crucial that compressors are efficient with regard to energy. When it comes to assessing the environmental compatibility of alternative solutions, it is not just the primary CO2 emissions caused by escaping refrigerant that have to be taken into account; indirect emissions caused by the consumption of energy also have to be considered. BITZER compressors have reached a very high standard in this respect – one that is now considered a benchmark in the industry, as confirmed by ASERCOM certification, which so far only BITZER’s SL compressors have received in the CO2 application field. The Association of European Refrigeration Component Manufacturers is a conglomerate of leading European component manufacturers in the heating, ventilation, air-conditioning, and refrigerating technology sector.

As well as developing and manufacturing CO2 compressors, BITZER focuses on comprehensive customer training. Regular training courses using functioning systems are held in its CO2 training centers in Rottenburg (Germany), Sydney (Australia) and São Paulo (Brazil). In Rottenburg alone, around 550 people from more than 30 countries have attended these courses since November 2010. The teachers provide both theoretical and practical basic knowledge about how to work with CO2 as a refrigerant. In the practical part of the course, they conduct highly realistic instruction on commissioning and troubleshooting in connected systems incorporating several evaporators. In addition to that, the teachers cover specific topics relating to BITZER products and CO2 applications.

Implementing a new technology in the market requires a balanced approach consisting of a comprehensive range of products, outstanding system characteristics, expert advice, and sound training. CO2 is one of many examples of this in the BITZER product portfolio.