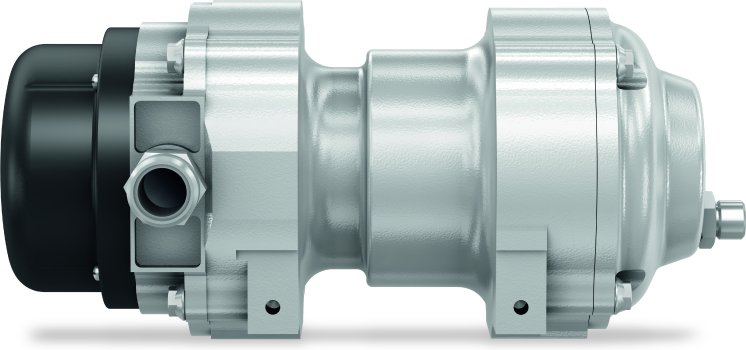

The major benefits of the two new semi-hermetic SPEEDLITE ELV2109 and ELV2113 scroll compressors over their predecessors, the ECH series, are their lower volume and 50% (9 kg) lighter weight with a cooling capacity ranging from 0.9 to 3.5 kW and 0.9 kW to 5.5 kW, respectively.

Ideal for bus and train applications

This makes them ideal for bus, train and many other vehicle applications. In such applications, every reduction in space and weight reduces fuel consumption, costs and CO2 emissions. Another benefit of the ELV2109 and ELV2113 compressors: SPEEDLITE scroll compressors can be used with supply voltages ranging from 24 VDC to 400 VAC, making them universal compressors for bus applications or to cool the cabins of farm or construction machinery. During the development of the entire range of compressors, BITZER focused on the optimal interaction between the scroll spirals, electric motor and frequency inverter. The result of these endeavours: BITZER integrated these three components into one compact system.

Flexible capacity control

ELV21 scroll compressors are also flexible in terms of capacity control. Thanks to the integrated, suction gas-cooled frequency inverter, the capacity can be controlled seamlessly and independently of the electric motor in a wide range of speeds of between 2,000 and 9,000 rpm. This allows the compressor to be adapted to all climatic operating conditions and ensures optimal cooling. “The new SPEEDLITE ELV2109 and ELV2113 scroll compressors offer wider application limits and a wider range of applications under higher condensing temperatures than their predecessors,” explains BITZER Chief Technology Officer Rainer Große-Kracht. “Additionally, as the scroll compressors are half the weight of the previous models, their lower fuel consumption rates are not only good for the customer’s wallet, but also the environment. And the cherry on top: SPEEDLITE ELV21 scroll compressors are not limited to just R134a as a refrigerant.”