Selection, integration and motion simulation of a component

Simulations of systems clear the path towards Industry 4.0 and the Internet of Things

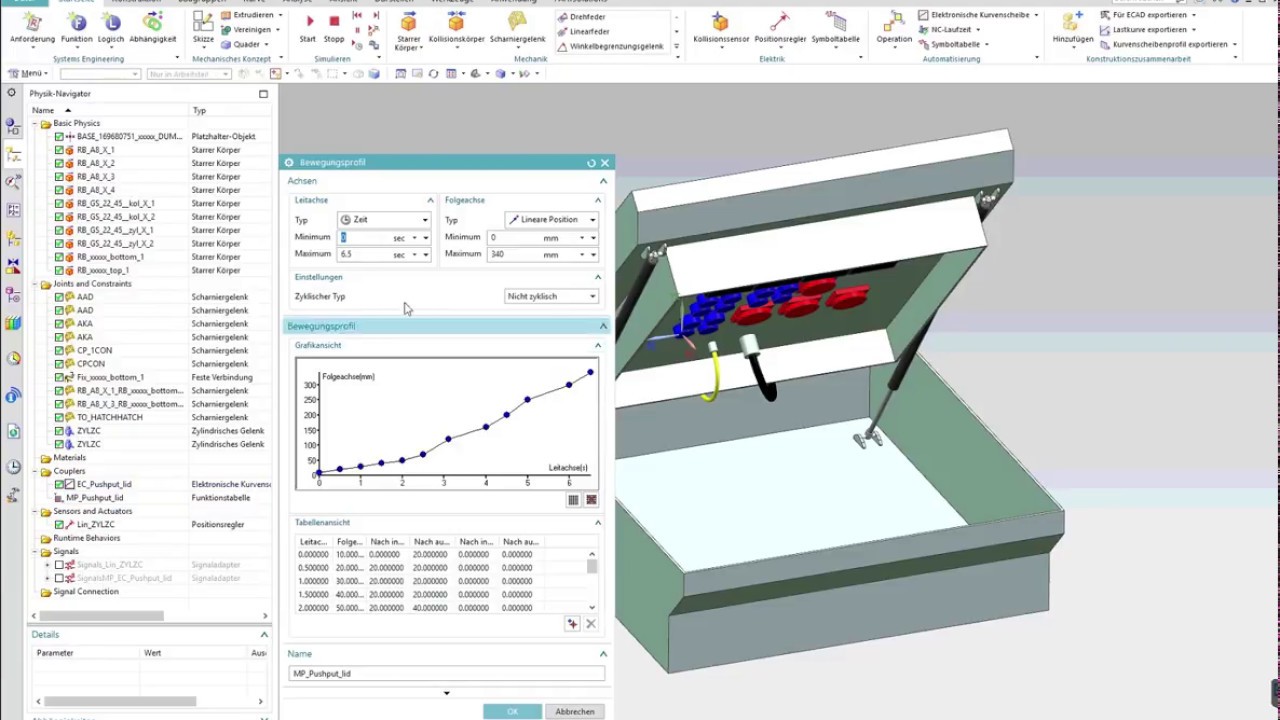

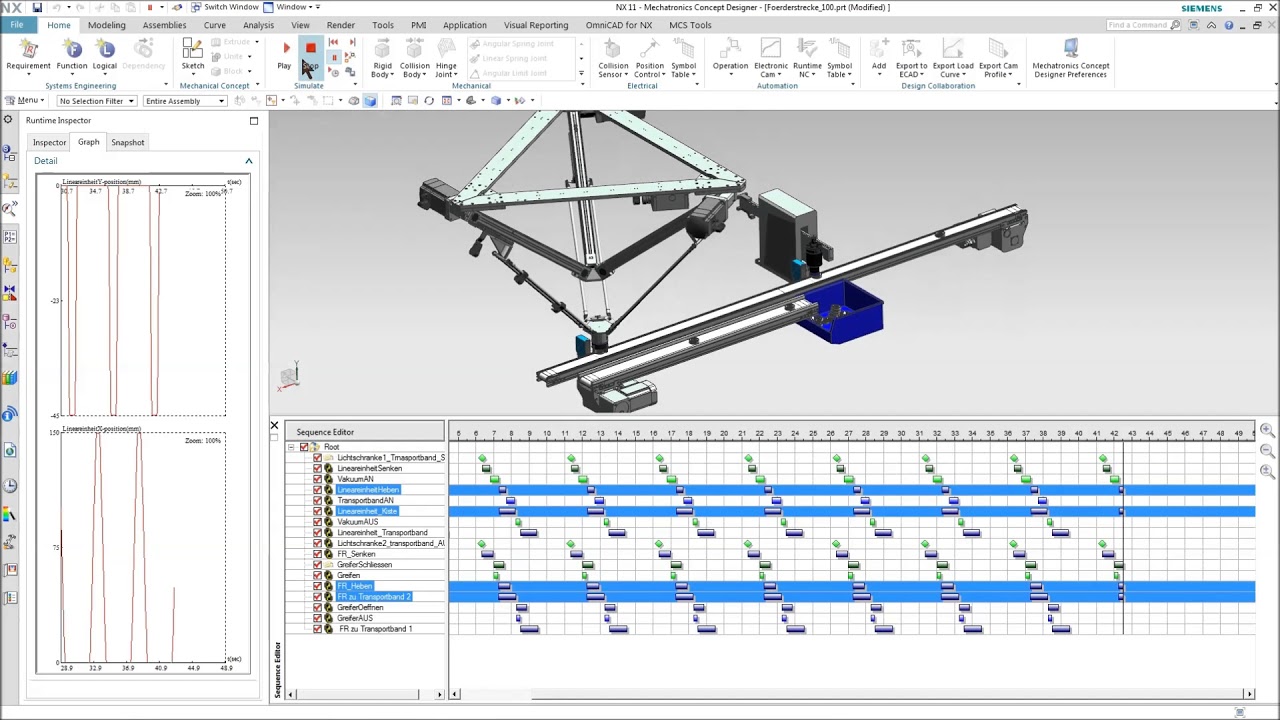

Software solutions for simulations, such as the Mechatronics Concept Designer (MCD) from Siemens PLM, contribute greatly towards Industry 4.0 and the Internet of Things (IoT). The MCD is thereby a consistent solution for automation development (integrated design and kinematic simulation) within the 3D CAD software NX. In conjunction with the so-called Digital Twin, it is possible to virtually test the commissioning of technical systems beforehand and digitally perform a careful coordination of control. This shortens the lead-time before the start of production.

Example of the simulation and virtual commissioning of a production plant

What constitutes an intelligent component and how is it prepared for simulations?

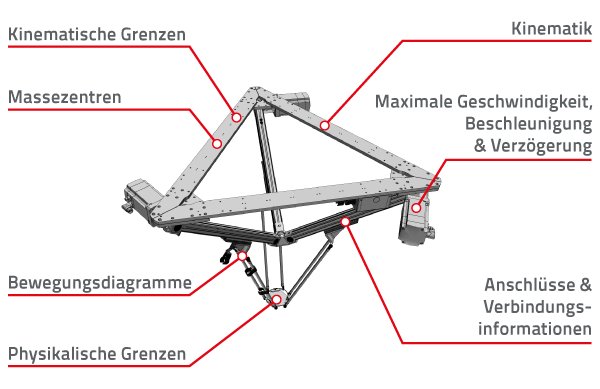

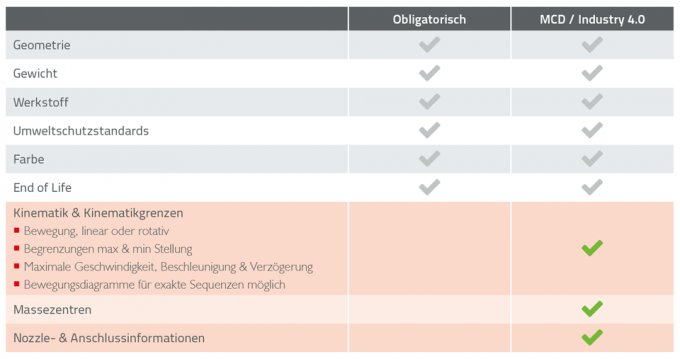

The geometry of a component alone is not sufficient for the design. With eCATALOGsolutions by CADENAS, the 3D CAD models contain intelligent functions that go beyond mere geometry and are thus well equipped for the age of Industry 4.0. First, the components must have kinematic information for simulations, such as direction of movement and degrees of freedom. Moreover, information about nozzle and connector as well as mass centers of each components are important, along with their physical values and limits such as maximum speed allowed, acceleration and deceleration.

So that further simulation software solutions can be used in the future, CADENAS defines metadata beforehand that corresponds to what is in the Electronic Product Catalog.

If you are interested in the Digital Twin research group or you wish to make your Electronic Product Catalog fit for Industry 4.0, then send us your query to [email=catalogs@cadenas.de.]catalogs@cadenas.de.[/email]