The SMS group, under the roof of SMS Holding GmbH, is a group of global players in machinery and plant construction for the steel and nonferrous metals industry. More than 14,000 employees generate global sales of some EUR 3.4 billion.

Parts management department provides high quality data

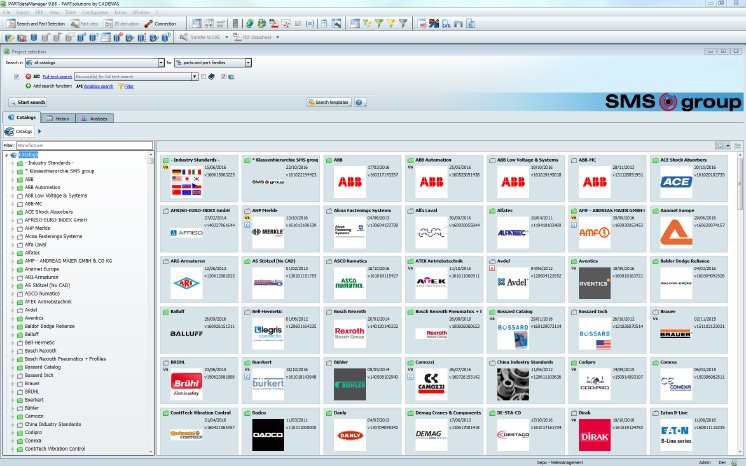

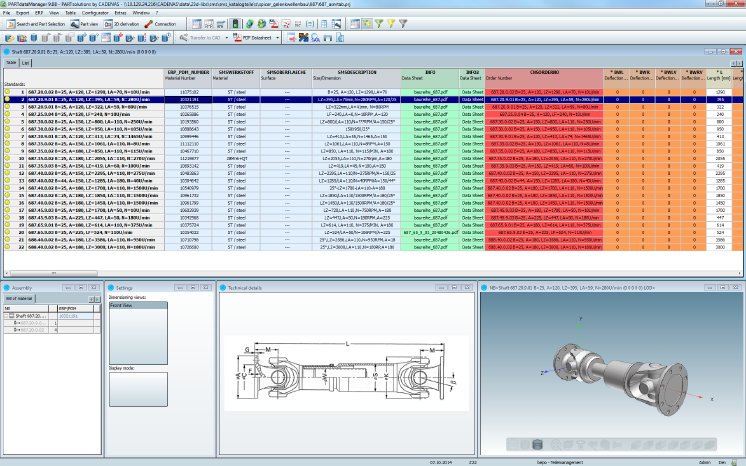

There is a central department at the SMS group responsible for all tasks around the topic of „parts management“. With the help of PARTsolutions the company’s design engineers are provided with, amongst other things, currently updated manufacturer catalogs and capable catalog parts with multi CAD. These are provided in many CAD formats including: Creo Parametric, Autodesk Inventor and Auto CAD. Moreover, SMS internal catalog and standard parts are created with their specific requirement as 3D CAD geometries and made available in the Parts Management System from CADENAS.

Central access to all locations for identical parts information

Numerous locations of the SMS group worldwide already access the Strategic Parts Management PARTsolutions. Parts information used to be stored at individual locations and were updated and made available only after hours on end. Parts data of the SMS group have been centrally stored on one server, the PARTapplication, since March 2015. Thus, all locations now have access to the same parts data, which are made available to design engineers much faster. „We are one of the first customers to use the CADENAS web service for the quick distribution of data to distant company locations. We are excited how well everything works,“ says Bernd Postaremczak, Head of Parts Management SMS group GmbH.

Challenges for parts management in a globally operating company

Especially with the international orientation of parts management, the SMS group currently faces a number of challenges. A parts management department is being established in India at this time. This means that, above all, the language barrier must be overcome. Previously most of the regulations for parts management have been in German, but now English is required. The same applies to the standards and data sheets as well as to the folder names, which must also be made available in English. In addition, international standards must be updated and, for example, sizes and dimensions given in international measuring units.

„Foreign sites are not to merely be extended workbenches in the future, thus our company has the target of integrating all SMS group companies in SAP by the year 2020. This means a change to the ERP system for all newly integrated locations, which will involve a number of challenges. For each conversion, all standard and purchase parts must be matched. Moreover, numerous new standards and new manufacturers at every location must be set up in SAP,” says Bernd Postaremczak, SMS group GmbH. „An effective parts management means constant data maintenance and PARTsolutions from CADENAS supports us optimally."

More information about the case study of the SMS group and CADENAS at: SMS group Case Study