The introduction of the Caparol Clean Concept in 2003 levelled the way for a new standard in the facade area. It was at that time that the term "nano-technology" was used. Here, the focus was placed on long-lasting cleanliness due to reduced adhesion of dirt. Caparol has been setting new benchmarks in facade protection since 2007 using nano-quartz matrix (NQG) technology. The NQG product line is characterised by long-lasting cleanliness, colour brilliance and a mineral character.

The well-proven NQG technology is based on a hard surface which is not susceptible to thermoplasticity (softening) and which does not soften even with extreme heat (e.g. in high summer). In this way soiling due to the adhesion of particles of dirt, fine particulates and spores is prevented. Any dirt briefly sticking to the facade is washed off at the latest during the next shower of rain. Swelling of the binder is prevented while the protective function and vibrant colours are retained.

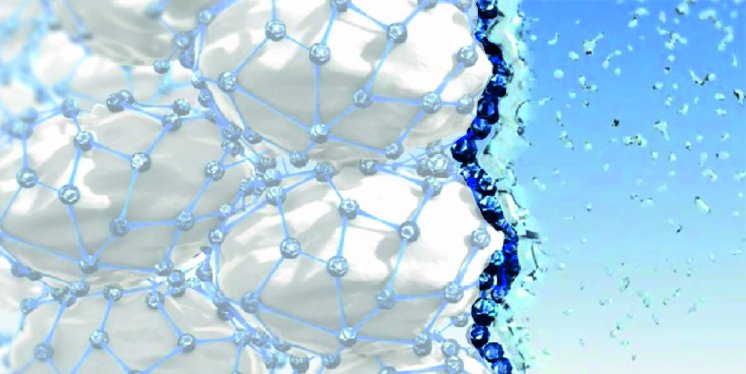

With the nano-quartz matrix technology nanoscale silicate particles are firmly and inseparably bound to the other binder particles during the manufacture of the organic binder. This produces a stable binder framework with inorganic pigments which ensures longer colour fastness.

Now there is a new NQG generation with improved formulation and even faster drying. Particularly the drying time of the facade is a crucial factor for minimising algae and fungal attack.

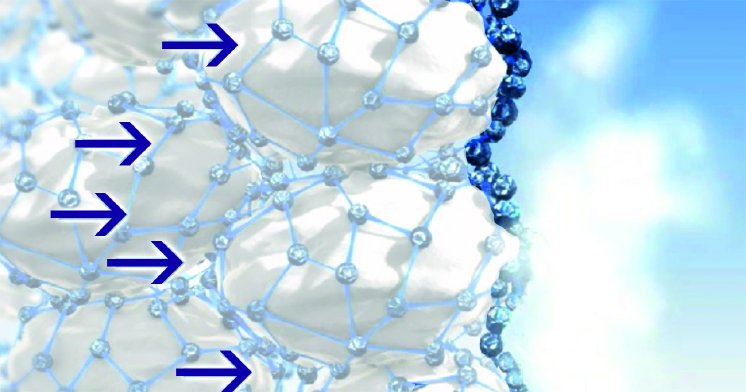

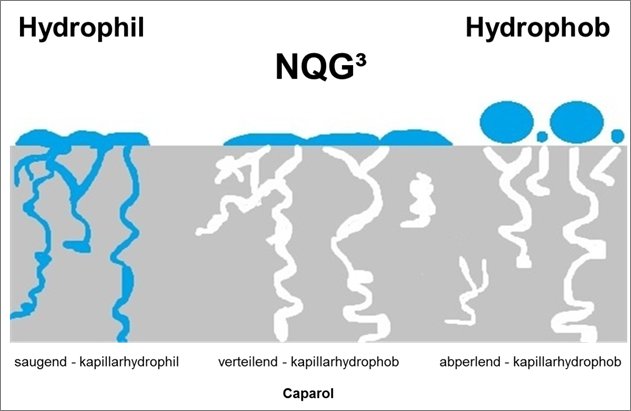

The "capillary hydro-active" drying management of the NQG³ paint functions as follows: Moisture is spread over the surface and is largely eliminated from the facade (Fig. 1). At the same time water vapour can penetrate to the outside and the moisture on the facade evaporates (Fig. 2). The surface structure of NQG facade paints facilitates a more uniform distribution of weather-related moisture. This effect causes quicker evaporation, because moisture cannot collect. The capillary hydrophobia ensures that moisture is largely eliminated from render and masonry and the conditions for microbial attack are made substantially more difficult (Fig. 3).

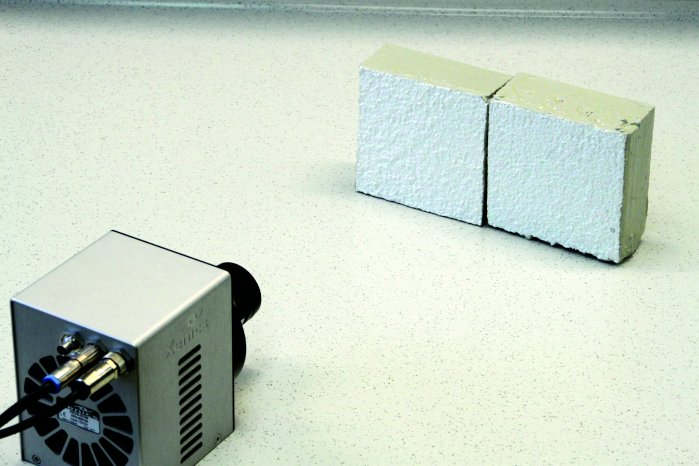

During the development of the NQG³ technology, comparative tests against readily available, high-quality facade paints (without nano-quartz matrix) were carried out. The declared objective was to prove the product promise of "even faster drying". This aspect is particularly important for preventing attack by algae and fungi.

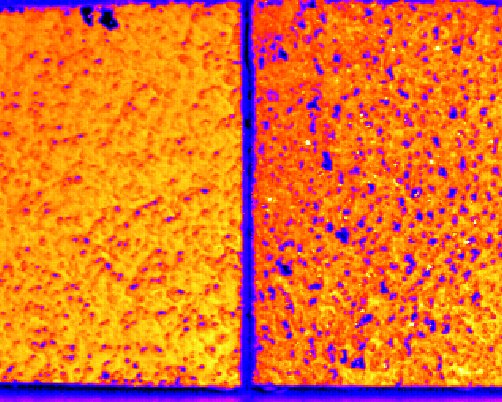

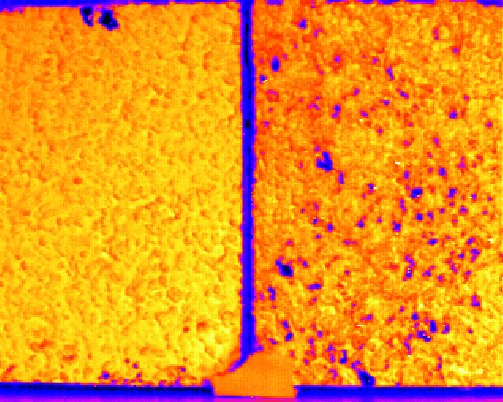

To clearly demonstrate the effect laboratory tests with measurement systems specially developed for this purpose were elaborated. In these tests NQG³ showed 30 percent quicker drying after intensive watering compared to the comparison paints. This was measured and visualised spectroscopically using a special infrared camera (Figs. 6 and 7). The darker the colour, the more moisture is located at this point on the surface. On larger, rendered test panels the difference could be clearly seen even without measurement equipment (Fig. 5).

This means that Caparol research has once again introduced decisive technical progress with innovative ideas. Consequently, it is now possible to visualise and reduce the main cause for attack from algae and fungi. This represents a milestone in the path to more sustainable facade coatings following the motto – longer clean x sooner dry x longer attractive.