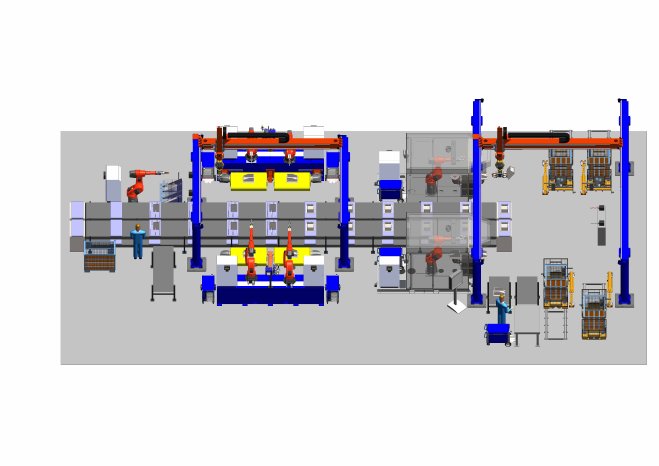

The CLOOS portfolio comprises simple, compact systems as well as complex, chained systems with automated workpiece identification and loading and unloading processes. “At the exhibition we will show that already today tool carriers, robots, power sources and master controllers successfully communicate with each other in CLOOS automation systems all over the world,” says CLOOS managing director Sieghard Thomas. The strength of the traditional company which will celebrate its 100th anniversary next year is the widely spread competence. From the welding technology, robot mechanics and controller to positioners, software and sensors – CLOOS supplies everything from a single source.

New QIROX Controller QC 2 robot controller

Among others, CLOOS will present the new control cabinet generation QIROX Controller QC 2. The QIROX Robot Controller is particularly designed to meet the requirements of welding technology and offers an optimum man-machine interface. Independently from chained systems with proven MES connections, the new robot controller generation QC 2 enables the bidirectional data transmission to host computer systems via PC-UA. The new servo technology ensures a dynamic movement and a high path accuracy of the robot during welding. The new QIROX Controller QC 2 is available in different sizes up to 8 (micro), 11 (master) and 20 axes (advanced).

Innovative software solutions for optimum data management

Other highlights are the new QIROX Operating System (QOS) with the new QIROX Technology Interface (QTI) and the new QIROX QWP operating software. They offer an even more user-friendly, intuitive operation, a considerable reduction of the programming times and a very dynamic movement of robots for efficient welding.

With QINEO Data Manager, Process Data Monitoring and RoboPlan CLOOS offers further innovative software solutions for the different requirements of connected production. Furthermore, CLOOS developed a complete information and communication tool named PC Suite in order to centrally record and save all incoming and outgoing data and to regulate the access. Thus the customer gets a data centre to manage the information as required.

Process diversity in perfection

Last but not least CLOOS will show new and proven welding processes for maximum productivity and quality. In the case of Tandem Weld two separate welding wires are fed and melted simultaneously in one molten pool. This results in a high deposition rate, a high welding speed and thus a low heat input. Since 1996 CLOOS has been the global market leader in Tandem Welding and has continuously developed this process. Also in the field of laser welding CLOOS sets new standards. The laser MIG/MAG Hybrid process is the combination of a laser beam with a MIG/MAG welding process in one common process zone thus using the advantages of both processes. The main advantages of Laser Hybrid Weld are highest welding speeds for an optimum efficiency at excellent quality.