High accuracy is the name of the game: the manufacturing industry seems to be increasingly committed to this idea. When it comes to micro-components – which are used in medical equipment, mobile phones and other precision devices – the highly accurate processing of various materials is also increasingly part of the specifications in cutting operations.

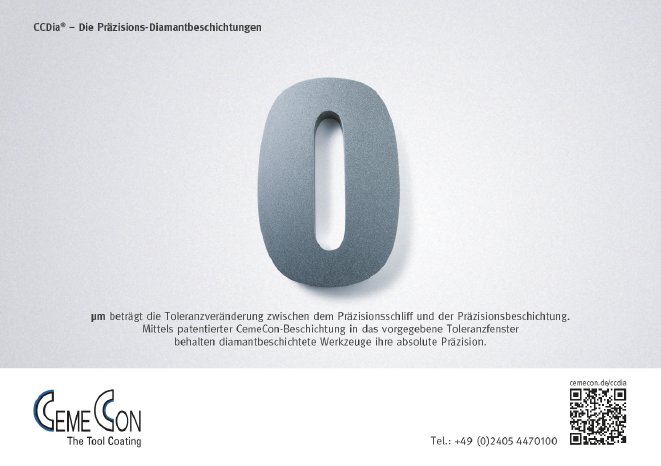

But extreme accuracy is also the number one priority for larger items: if, in particular, smooth surfaces or accurate contours are needed, tolerances are usually in the µm scale. This not only makes particular demands of the cutting tools, which need absolutely precise cutting geometry, but also of the coatings, which must alter the contouring accuracy as little as possible.

As a developer and manufacturer, CemeCon AG provides high-quality coating solutions for cutting that can meet these requirements. Manfred Weigand, Product Manager at CemeCon: "As technology continues to get smaller and smaller, so too must the machining tools. Milling cutters with a diameter of 0.5 mm or less are not uncommon. Coatings have to be able to follow suit: they cannot be too 'thick' and affect how the tool functions, but at the same time they must have a high level of abrasion resistance,"

The tightest of tolerances are adhered to

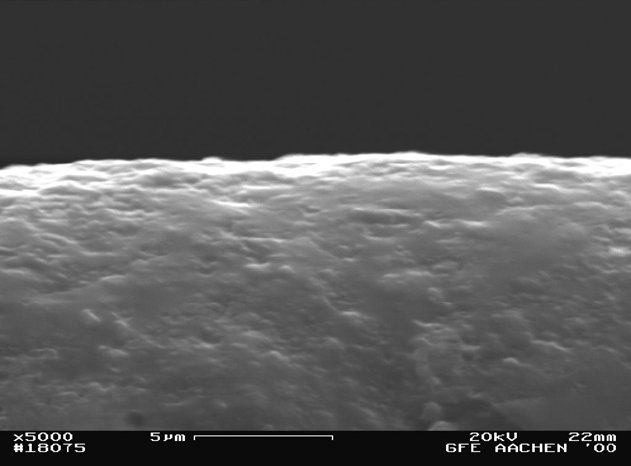

CemeCon manages to ensure that this is the case by using a special CVD process for manufacturing multilayer CCDia® series diamond coatings. The patented combination of crystalline and nano-crystalline structures allows a coating structure to form with excellent hardness and wear resistance properties, perfect smoothness and excellent thermal conductivity.

Manfred Weigand: "The multilayers of our CCDia® series can be applied in layer thicknesses of 3 to 15 µm, depending on the intended use. This leads to precision grinding and coating compared to no tolerance change. Only the tolerance position changes, guaranteeing exact contour accuracy and sharpness of the edges."