Commercial aerospace and urban air mobility manufacturers face a challenging problem: Their vehicles have to be extremely lightweight, strong and stiff. This mandates the use of lightweight fiber composites such as sandwich components. But the manufacturing of those complex parts with their demanding multi-material mix is difficult: How to integrate the lay-up of different materials into one automated process? And how to facilitate state-of-the-art process and quality control?

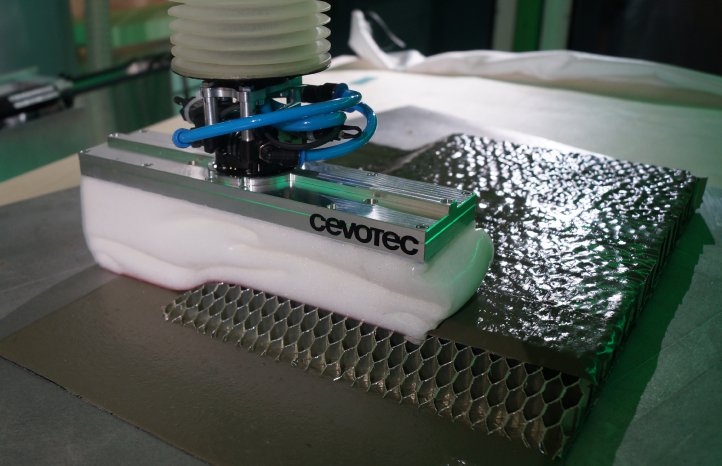

Cevotec answers both questions with their production systems based on the Fiber Patch Placement (FPP) technology: SAMBA Multi features parallel feeding units for processing up to 4 different materials and placing them precisely on 3D sandwich cores. By mounting the placement unit on a linear axis, the concept also enables the production of particularly long and wide components in aerospace applications. Adapted to the size of specific components, the patches are scaled to letter-size dimensions, providing for a high material throughput. An integrated, automated gripper station enables the switching of gripper sizes during the process, so that smaller patches can be used for lay-up in high-complexity areas of the part.

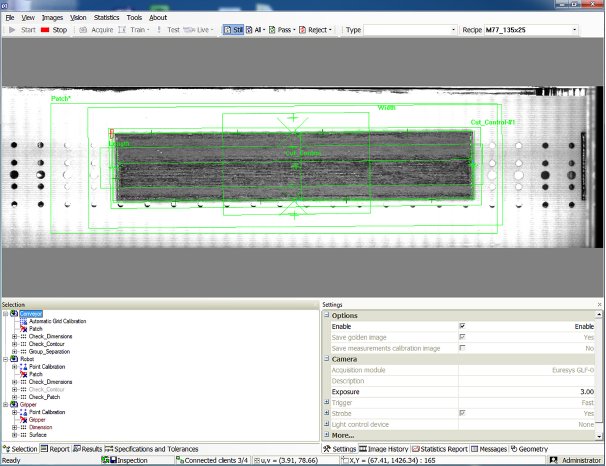

Felix Michl, CTO of Cevotec, further explains: “We have implemented the Fiber Patch Placement technology as a series of individually-controllable patch placement processes, which in turn makes the entire component production cycle highly controllable. One of our most important features is the in-process material control with two vision inspection units and self-correcting algorithms. The first unit identifies the quality of each patch that is cut. The second unit identifies the relative position of the patch on the placement gripper once picked up. Thereby, the in-process quality control system ensures that only 100% in-spec raw material is being placed precisely on its intended position.”

Additional industry 4.0 modules for SAMBA systems cover predictive maintenance and in-depth analytics on production data. Analyses of production data enable key insights into process reliability and repeatability. Correlating the data with actual layup quality enables engineers to adjust process parameters in real-time and – in the future – also AI-assisted. Ultimately, part quality will be ensured only by controlling process parameters.

Such advanced process controls enable manufacturers to improve not only their part quality, but also equipment reliability & availability. “These benefits usually come as an upside to baseline savings of 20% – 60% in production cost & time that have been demonstrated by the technology when switching from manual lay-up to Fiber Patch Placement,” as Thorsten Groene, Managing Director of Cevotec, reports.

Visitors to Composites Europe, Stuttgart, can meet Cevotec at booth C86-18 (Composites Germany Pavillon). At CAMX (September 23-26 in Anaheim, California) we are looking forward to welcoming you at booth G71 and we will speak in detail about our Composites 4.0 Process Control in an educational session. During the Advanced Engineering Show (October 30-31, 2019 in Birmingham, UK) we can be found at booth L74 and Dr. Neven Majic will explain how the discretization of fiber lay-up enables our self-corrective process control at the Composite Forum.