Today's electric vehicles all use lithium ion batteries for storing the electrical energy. This technology is well known in the field of portable computers and entertainment industry. Mass production mainly of round cells has significantly reduced the price, so that nowadays hardly any other battery type is used.

In the automobile combinations of a several dozen single batteries are interconnected to so-called battery packs. This makes it possible to achieve the necessary voltage level and especially the storage capacity to provide the vehicle the range required by the customer.

However, lithium batteries are sensitive electrochemical elements. Total discharge and overcharging are generally avoided electronically, since damages of the separator between the electrodes due to generated dendrites (deposition of compact metal) can lead to a loss of storage capacity or even to short circuit. Usually these BMS (Battery Management and Monitoring Systems) are already integral parts of Li-ION battery cells.

But also too high temperature or load at low temperature lead to an earlier ageing of the Li-ION batteries or increase the risk of damage. At costs for a battery pack of several thousand EUR per electric vehicle this is a damage that must be avoided in any case. Not only the range, but also the number of possible charging cycles are key factors for the purchasing decision. Who wants to spend one-third or more of the vehicle value after only a few years to purchase a new battery pack.

Especially under load, the densely packed single batteries become very hot. The current flow generates heat loss that must be removed efficiently. This is realized by forced air cooling (fan) or with liquid cooling (water cycle) depending on the manufacturer and performance class. In total, this is an engineering challenge which is quite easy to solve by technological acquisitions from the conventional electronics and vehicle technology.

However, an additional problem is the sensitivity of Li-ION batteries during charging and discharging processes at low temperatures. They accelerate the ageing of the cells and consequently reduce the possible duration of use. To cope with this problem, a part of the energy stored in the cryogenic battery must be used to heat up the battery pack and thus the electrolyte.

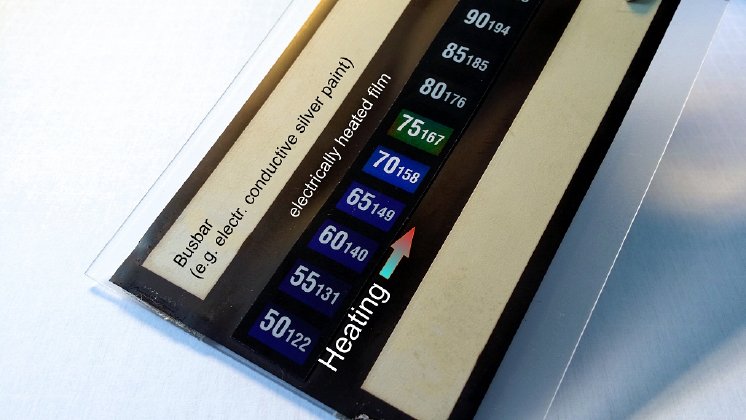

The electrically heated film CMC 70010A which can be placed helically around the individual elements called "coffee bags" represent a very elegant method. They release an easily regulated amount of heat (max. approx. 1 kW / m²). The heat development starts immediately when applying a voltage. Thus, the battery is already heated immediately after the start-up process and brought in the optimal working range of 0-40 °C.

For this task CMC Klebetechnik offers a polymer film with a thickness of only 50 microns (CMC70010). With 100 ohms / square and a temperature stability of far more than 200 °C it has optimal conditions to be installed space-saving even in tightly packed battery packs. The resistance is very constant over the whole temperature range and changes only slightly also due to ageing. These are ideal conditions to reliably survive the entire lifetime of the battery. In addition, the film is inherently flame retardant according to UL94 VTM-0.

Due to the special structure the film retains its function also with e.g. puncture or kinking other than with surface heating elements with copper tracks. Since the film is only destroyed at far more than 300 °C, it has an enormous safety buffer. The resistance against thermal ageing (lifetime) is therefore extremely larger compared to e.g. polyester films.

Interested parties will receive samples which are "adjustable" by simple cutting with regard to thermal output, voltage class and current flow. Manufacturer contact: www.cmc.de