While commonly used wired industrial communication enables the collection of data in some parts of the factory, data needs to be collected throughout the factory – anywhere and without exceptions. Access to data from sensors across the factory enables powerful analysis and decision-making in addition to optimization of manufacturing planning and processes. The collected information must be reliable, and data access must be scalable to thousands of sources. Essential data collection in an industrial environment can be very challenging - inside machine parts, on fast-moving or rotating platforms, or at remote locations.

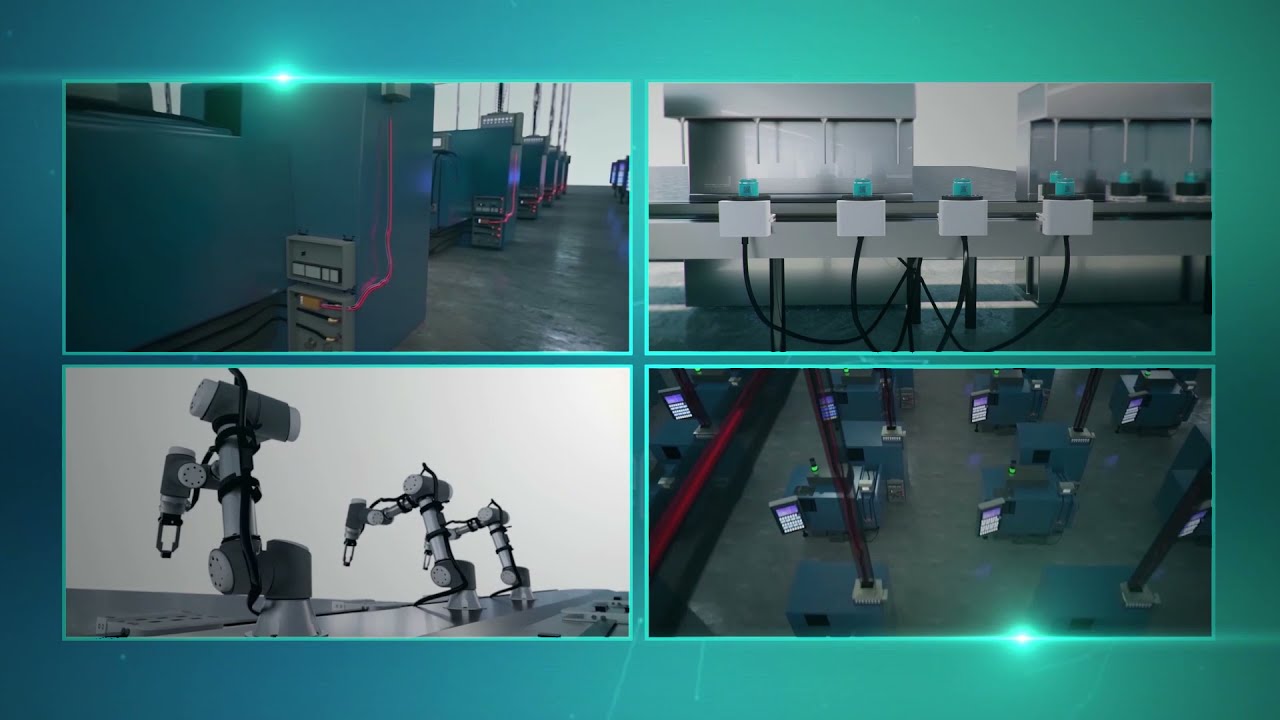

The NXTGN and CoreTigo solution is addressing these needs by enabling a fully integrated wireless solution at the OT and IT levels. It is designed for factory automation and reduces the dependency on cabled communication, thus enabling cost-effective and simple deployment. As common wireless technologies (Wi-Fi, BLE, Zigbee and cellular) are not robust enough for the harsh factory conditions, industrial-grade IO-Link Wireless communication is utilized for collecting sensor data on the machine and transmitting it to the Gateway. From there, the information is sent onwards to the cloud application via cellular communication. The solution is comprised of the following components:

- NXTGN CM007 Cloud Gateway – An integrated cellular and IO-Link Wireless Gateway enabling OT communication to devices via IO-Link Wireless, and IT level communication via a cellular uplink. CoreTigo’s IO-Link Wireless Master 1T SOM (System on Module) is integrated inside the Gateway along with an integrated SIM card that transmits data to the cloud application via 4G/LTE M or NB-IoT (with 2G as fallback).

- CoreTigo IO-Link Wireless Bridges and Hubs – The TigoHub and TigoBridge turn digital, analog or IO-Link sensors/actuators to IO-Link Wireless devices. Up to 8 IO-Link Wireless devices can communicate directly with the embedded IO-Link Wireless Master in the NXTGN Gateway at a low latency with ultra-high reliability, while coexisting with other wireless networks in the factory. These IO-Link Wireless devices are installed on the machines, connected to the various sensors, and send the data to the NXTGN CM007 Cloud Gateway.

This solution simplifies upgrades and relocations of existing machines and production lines with wireless sensors. Simple Integration to enterprise and cloud-based applications is achieved. Retrofit of existing machinery is easily done with the TigoBridge and TigoHub off the shelf products, allowing a plug-and-play solution. Removing the communication cables results in simplified maintenance and unplanned downtime reduction due to cable wear and tear.

To support large scale operations, hundreds of wireless units can be used within a single workcell or machine area. The scalable nature of NXTGN’s and CoreTigo’s offering allows it to be used both in small and large scale deployments. As a result, a very cost-effective real-time full-view of the entire production line is gained, all the way from the factory floor and up to enterprise and cloud-based applications. Thus, powerful analytics and business intelligence capabilities are used for improving overall performance and operational efficiency, as fact-based decisions are now possible.

“The universal nature of this combined solution which was designed specifically for factory automation makes it so unique”, Says Martin Reich, CoreTigo Business Development Director DACH. “On one hand, NXTGN’s cellular Gateway, operates worldwide on a broad range of network types, allowing simple cloud connectivity, and on the other, CoreTigo’s technology, bridges the gap of the reliable wireless connectivity on the factory floor.”

“What was most important for us with this solution, was to make it completely flexible”. Says Patrick Franke, NXTGN Managing Director. “It is designed to coexist and be implemented in an industrial environment, while using wireless connectivity both at the OT and IT level, enabling it to operate on any device type both on existing and new machines”.

At SPS Smart Production Solutions 2022 expo (8-10 November) in Nuremberg, Germany, the two companies will be presenting their solutions:

- CoreTigo: Hall 5, Booth 338. To schedule a meeting with CoreTigo & get a free ticket, click here.

- NXTGN: Hall 5, Booth 158. To schedule a meeting with NXTGN & get a free ticket, click here.

About NXTGN

NXTGN SOLUTIONS GmbH supports companies with process and software challenges of the digital transformation. NXTGN offers support for digitalisation initiatives and for the optimisation of business models or processes. Founded by a team of successful CRM, ERP and BI experts, NXTGN offers consulting and implementation of IoT solutions, connectivity & business software from a single source. From sensor to business model. www.nxtgn.de