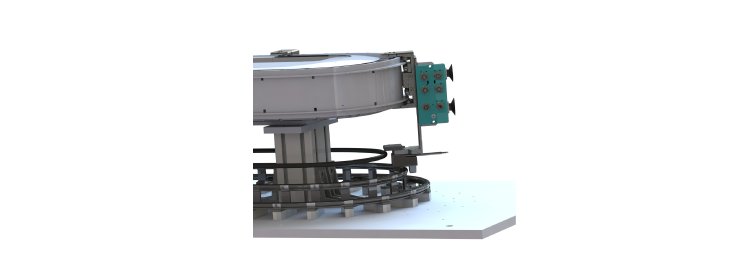

By combining VAHLE´s inductive power transmission systems with CoreTigo's IO-Link Wireless system, it is possible to offer the most comprehensive range of products for System Integrators, Machine Builders, and production lines using Transport Track systems. The joint solution further increases the independence of Transport Track systems by enabling interaction directly on the movers for real-time control and monitoring – something that could not have been achieved up till now. VAHLE and CoreTigo enable maximum scalability, speed, and modularity to support Transport Tracks of any size and shape, in addition to compatibility with any type of Transport Track system in the market.

"We want to improve our service offering not only by further developing our own products, but also provide our customers with a comprehensive overall package through targeted strategic partnerships," says Achim Dries, CEO of the VAHLE Group. "CoreTigo's real-time wireless communication systems are an optimal complement to our inductive energy supply solutions and significantly expand the portfolio of system solutions for VAHLE," Dries emphasizes.

IO-Link Wireless has been specially developed for industrial automation and offers the highest reliability as a wireless communication solution. “IO-Link Wireless demonstrates its strengths in real-time control and monitoring and is designed as a communication solution for high-performance applications and high-speed motion. This makes it possible to implement completely new applications for the packaging industry in order to increase flexibility, adaptability, and efficiency of the machines to a new level," says Martin Reich, Director of Business Development DACH for CoreTigo.

The joint solution from VAHLE and CoreTigo is driving benefits throughout the various stages of machine design, production and maintenance. Machine capacity is increased by performing actions while in motion. A broad range of package variations (size, weight, shape, material) can be supported efficiently within a single machine. Changeover and setup times are significantly reduced. Machine footprint is reduced due to cable reduction and less external robotics/equipment. Greater intelligence is achieved through predictive maintenance & analytics that are based on data collected from high-speed moving components. All these contribute both to the financial performance and sustainability of the manufacturing plant – as waste, footprint and energy consumption drop, while efficiency and the ability to use sustainable materials increase.

Factory Automation goes wireless – both in power and connectivity

"IO-Link Wireless is an important building block for the realization of new machine designs," said Eran Zigman, CEO of CoreTigo. "Both technologies are key for enhancing machines and complement each other perfectly. Wireless power and connectivity are a necessary element for enabling adaptive machines and for the implementation of Industry 4.0."

"Especially for manufacturers of packaging machines who need a highly available communication solution with low latency and deterministic behavior for the real-time control and monitoring of their systems, we can offer significant added value with IO-Link Wireless," says Dries. "The strategic partnership with CoreTigo enables us to quickly react to the dynamic market requirements in various automation fields. Customers in various areas will benefit from this.”

VAHLE and CoreTigo are already implementing this joint solution along with Machine Builders and large global manufacturers. At the end of March 2022, VAHLE and CoreTigo outlined their solutions in the joint webinar "Empowering Motion: Wireless Data & Contactless Power for Sensors and Actuators". A recording of this session may be viewed here: https://youtu.be/vnUwQHgJXg8

Further webinars, joint product presentations, and trade fair appearances are already being planned.

Further information about VAHLE can be found at: https://vahle.de

For more information about CoreTigo, please visit: https://coretigo.com

About Paul VAHLE GmbH & Co. KG

Paul Vahle GmbH & Co. KG is a system provider for mobile industrial applications. Since its foundation in 1912, the company has been supplying individual energy and data transmission systems worldwide for a wide range of applications. VAHLE focuses on the crane technology, intralogistics, port technology, automotive, people mover and amusement rides sectors. The company is well-known for the development of the first copper conductor rail by Paul Vahle in 1912.

Paul Vahle GmbH & Co. KG has its headquarters in Kamen and is part of the VAHLE Group. The value-oriented family business thinks and acts sustainably and stands for quality, innovation and solution orientation. Worldwide, the group achieves sales of over 120 million euros. Of the more than 750 employees, about 550 work at the German locations in Kamen and Dortmund and in twelve national sales offices. VAHLE is active in more than 50 countries worldwide, with thirteen subsidiaries and agencies.