Presented for the first time at EMO Italy 2021, the jointly developed solution, which converts the clamping jaw into an intelligent work tool, gained tremendous interest throughout the industry. Consequently, it will be presented again live at this year's SPS Italia 2022 (from 24 to 26 May in Parma / Hall 6 / Booth C023) and Hannover Messe 2022 (from 30 May to 2 June in Hanover / Hall 9 / Booth H77) by CoreTigo.

Later this year, it will be featured by Roehm simultaneously at AMB (13-17 Sep, Hall 1, Booth E50) and IMTS/Hannover Messe USA (12-17 Sep, West Building, Level 3, Booth 432343) and later again by CoreTigo at SPS Germany (8-10 Nov) and the Rockwell Automation Fair (16 to 17 Nov in Illinois).

At the upcoming SPS Italy and Hannover Messe exhibitions, CoreTigo will demonstrate live its latest IO-Link Wireless integrated iJaw intelligent clamping solution.

Flexible Solutions for Machine Tools

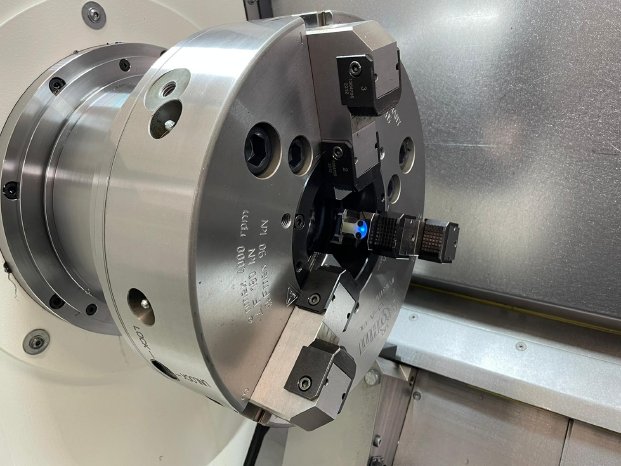

Traditionally clamping workpieces require an experienced and skilled operator for precise handling. Even on state-of-the-art machine tools, the clamping force of the chuck acting on the workpiece is manually adjusted by an operator. However, the manual setting can lead to deviations during the clamping process. If, for example, the workpiece is clamped too hard, it may damage the workpiece. Too loose clamping can lead to workpiece losses during machining. These may very well lead to damage to the machine and/or the tool. Until recently, there was no reliable way to measure the clamping force when machining during ongoing production.

Precise measurement directly at the clamping point

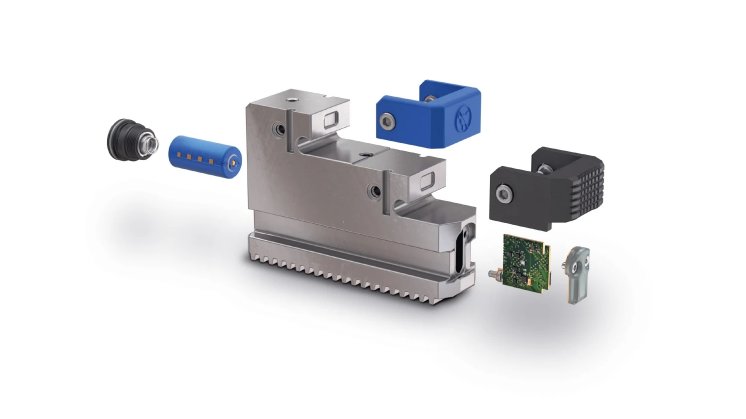

The intelligent clamping jaw iJaw was co-developed by Röhm, the clamping device specialist, and CoreTigo, the leading manufacturer of the industrial wireless communication technology IO-Link Wireless.

The iJaw solution supports the precise clamping of the workpiece. To enable the measurement of the clamping force directly at the clamping point, the iJaw contains various integrated sensors that allow real-time communication. The measurement data is transmitted wirelessly to CoreTigo’s Master, which is connected to the machine control system via an integrated Industrial Ethernet interface or directly to IoT or cloud applications. The data can then be displayed, analyzed and stored.

Predictive Maintenance and Predictive Quality

Even during the machining of the workpiece, the iJaw continuously sends the data of the measured clamping forces and enables early detection of changes, i.e., deviations from the setpoints. The measured values and data recorded in real time also provide important information for the prognosis of future repairs and/or tool wear. The iJaw thus alsosupports the preventive maintenance of the machines and tools in order to avoid unplanned downtimes and to maintain and document product quality in the manufacturing process.

The iJaw Intelligent Machine Tooling Case Study at ARC European Industry Forum 2022

Being recognized by the industrial community as a case-study for the Industry 4.0 digital transformation and enabler of OT-IT convergence, the iJaw was recently featured on ARC Advisory Group’s European Industry Forum. In this session, led by CoreTigo’s Chief Strategy and Marketing Officer – Gabi Daniely, and Röhm’s Head of Business Development – Thomas Roth, the benefits and new applications made possible by industrial wireless connectivity were presented. To watch the full session, please click here.

The IO-Link Wireless Ecosystem Collaboration

At SPS Italy and Hannover Messe CoreTigo will present various IO-Link Wireless based Mass Customization applications live with its partners. Röhm is an integral part of the continuously growing IO-Link Wireless ecosystem, alongside companies such as B&R, Laumas, VAHLE, Rockwell, Schneider, Zimmer Group and many other companies. The interoperability characteristics of the global, worldwide standard are firmly anchored in the DNA of IO-Link Wireless.

To visit CoreTigo in person at SPS Italy 2022 or Hannover Messe 2022, schedule your meeting with CoreTigo executives and get a free ticket, click here: https://www.coretigo.com/2022events/

About Röhm

Röhm GmbH, with its headquarters in Sontheim an der Brenz (Baden-Württemberg), Germany and production sites in Dillingen (Bavaria) and St. Georgen (Black Forest), specializes in the development, design and manufacture of high-precision, robust and durable clamping and gripping devices. The products are "Made in Germany". Röhm's clamping and gripping devices are used worldwide by almost all renowned manufacturers in the automotive industry, railway engineering, clocks and watches, medical technology, power engineering and in woodworking. Röhm has its own subsidiaries in France, Italy, Switzerland, Spain, Poland, USA, China and Mexico. Founded in 1909, the company quickly became known worldwide for its drill chucks. To this day, Röhm develops and produces drill chucks at its Sontheim site, which are used by almost all manufacturers worldwide on stationary and hand-held power tools for screwing and drilling.