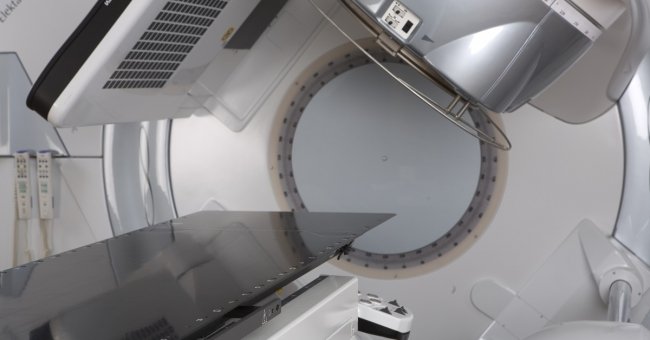

Elekta develops sophisticated, intelligent tools and treatment planning systems for radiation therapy, radiosurgery and brachytherapy. Its workflow enhancing software systems are further used across the complete spectrum of cancer care. The company has clear objectives to be a global Manufacturing Excellence Centre for Medical Devices, requiring strict enforcement of Manufacturing Quality Standards along with competitive, qualitative and cost effective processes for production.

Critical Manufacturing’s Medical Device MES offers unique differentiation and flexibility for the Medical Device and Diagnostics Industry. The Critical Manufacturing solution for Elekta will provide them with real time visualization of the shop floor, advanced planning and scheduling, master data management and complete enforcement of the entire manufacturing process, including materials, works instructions, operator certification and equipment management. Importantly, it will provide real time dashboards for monitoring KPI’s and fully electronic, searchable device history records (DHRs) allowing complete product traceability that will significantly reduce risk and streamline audits. The system simplifies the compliance process for all international compliance standards including FDA title 21 CFR Part 11.

Mark Kaak, VP Global Manufacturing at Elekta, commented, “We selected the Critical Manufacturing solution because it gives us the flexibility and agility to take our manufacturing to a new level of excellence. The Critical Manufacturing team show total commitment and enthusiasm and their solution was a perfect fit for our global operations. The system will help us bring together information across the three manufacturing sites and optimize shop-floor operations based on resource availability and the highest quality standards.”

The Elekta brand is associated with excellent product quality and value. The new MES will help both enhance quality and ensure products are produced at the ‘right cost’ for customers. It will increase the integration between processes and give complete real-time visibility and intelligence across the three manufacturing plants.

Francisco Almada Lobo, CEO at Critical Manufacturing said, “We are delighted to be working with Elekta. We have placed significant investment in ensuring our MES meets the precise needs of the Medical Device industry where quality, traceability and the production of safe products are all of utmost importance. Critical Manufacturing is fast gaining momentum in the MedTech Industry and companies like Elekta are recognising the need to bring increased agility to their business so that they can continue to innovate, compete and grow in a rapidly evolving market place. Our solutions are designed to ensure manufacturers have a pathway to develop their plants into smart factories that deliver the highest quality, consistent results and superb efficiency even for highly customized orders.”

Mark concluded, “We see this MES as a strategic investment and the whole company was involved in the selection process to ensure we got what we need to meet our goals for the future. It will help us optimise our production, efficiently meet specific customer demands and simplify regulatory compliance. It will also give us the information we need to have a deeper understanding of processes and workflows so that we can continue to further optimize and innovate across our plants.”

The system provided by Critical Manufacturing will initially cover three manufacturing sites with the possibility to extend to additional sites in the future.