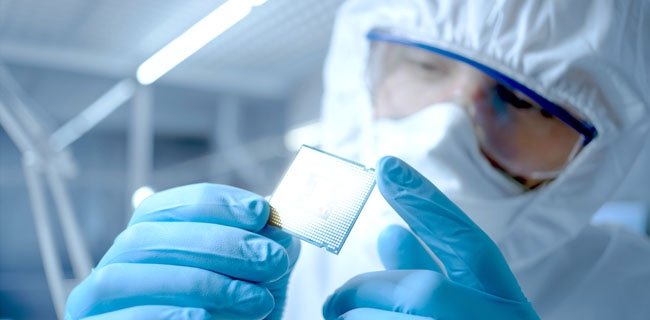

With a growing emphasis on innovation, MES must prepare for future compatibility with emerging technologies to ensure they are configurable, personalised and adaptable to future-proof businesses. The webinar covered these points, giving tactful solutions by our experts on how I4.0 can help companies move forward seamlessly in Semiconductor Manufacturing.

Challenges that the Semiconductor industry faces

“As pioneers in industry 3.0, the Semiconductor industry has led the way, and as most pioneers, it’s hard to step into the next big revolution.”

An old MES solution will limit a company’s ability to be competitive today and into the future. Increasing overheads for maintenance will be accompanied by a growing inability to adopt new technology choices that can increase productivity, reduce costs and improve quality.

Scott explains that the total semiconductor sales this year globally are projected to go beyond 350 billion US dollars, spread across different sectors all with different requirements. This only heightens the likelihood of challenges that MES systems face as they struggle to support OEM’s.

Julie goes to comment further, that we can expect such challenges as it’s difficult to rebuild complex code one building block at a time, even more-so when some code of a system may not even be visible nor understandable for some companies.

So, how can Industry 4.0 help?

With I4.0 you can expect to;

- Lower the cost of small-runs

- Improve your yield, reliability and quality

- Speed up your business process

- Have greater visibility across the value chain

- Have greater agility to respond more quickly

- Have your own new approach for the new economy

“The scalability of this kind of a system is dramatically different from what we knew and what most companies use today.”

There is no right or wrong migration strategy and the process selected is highly dependent on choosing one that fits the needs of the plant.

I4.0 can mine data more effectively to get more meaningful information, as a result of horizontal integration, which can;

- Accelerate product and improvement cycles

- Free up working capital

- Reduce cycle time of the overall value chain

- Boost the company’s bottom line

The Semiconductor industry was probably one of the first to embrace the idea of MES. The problem is that some of these systems still exist and are so embedded into the production process, that changing them is a complex task.

To listen to the full webinar, follow this link