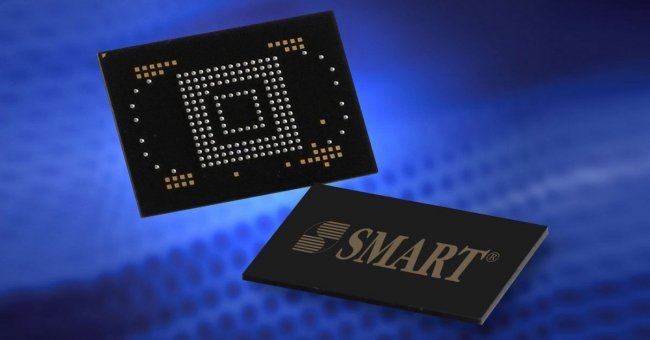

SMART manufactures sophisticated memory products including DRAM, and LPDRAM, eEMC, eMMC, and microSD, and as the production volume grows, managing flows in the old fashioned way turned to be insufficient. Internally developed WIP tracking system and recording data in Excel did not allow for close yield monitoring or data analysis to prevent defects, and will now be replaced by complete automated data collection and standardized production flows. As a result SMART will achieve full WIP traceability complemented by quality and SPC, recipes and equipment selection and tight control of time windows between processes.

“Moving from a manual system is a major thing. We are changing the culture, not just the system, for all the levels – engineers, managers, and operators”, says Francisco Javier, Equipment and System Engineering Manager. “By implementing a modern Manufacturing Execution System like cmNavigo, we are assured that all processes have strong controls. I would not choose differently.”

Click to read the full Press Release