In an interview with the winners of the 2016 Smart Story Awards, the top winning story from Critical Manufacturing raised some questions about the shop floor. More specifically, attendees wanted to know more about shop-floor decentralization. Here's the full answer:

In Industry 4.0, shop-floor decentralization is a truly compelling requirement. The vision of Industry 4.0 is production that’s able to meet new needs quickly and cost-effectively at high quality. This requires reducing the cost, changeover time and reliability of making products in small quantities or even one-off. With such a high percentage of unique one-off products, it is virtually impossible to optimize the shop-floor with a centralized approach.

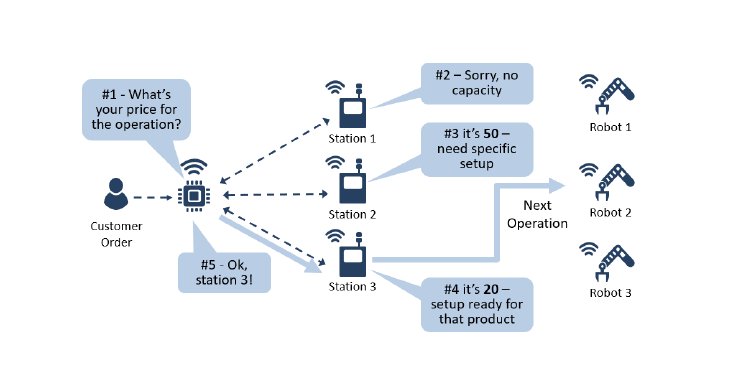

In fact, Industry 4.0 envisions a marketplace on every shop floor – and possibly in every supply chain. In the marketplace, demand comes from smart materials and products that require transformation steps and smart lines, equipment and tools are the suppliers that can perform the transformation steps. Products will broadcast what they need, and production resources will declare their bid to do the work at a certain price based on their capabilities, performance and availability.

Another term for these smart players in the marketplace is Cyber-Physical Systems (CPS). CPS are objects (such as products, materials or carriers) with embedded software, internet of things communication and computing power. Based on their industrial internet of things (IIoT), connectivity and computing power, CPS have self-management capabilities. This is a reality already. Sensors, actuators, communication and computing power are so small and affordable that in more and more cases products, materials and carriers can be intelligent.

Manufacturing equipment with those same IoT capabilities are Cyber-Physical Production Systems (CPPS). This software enhanced machinery also has its own computing power to leverage a wide range of embedded sensors and actuators. It is the combination of CPS and CPPS that will form marketplaces, and likely trigger significant changes in manufacturing production and control, towards completely decentralized systems.

So how can you control, monitor and optimize the shop floor? That is the role of MES. However, not just any MES. It must manage this decentralized environment, even if the MES is physically centralized. In other words, the logic in the MES must be able to model and interact smoothly with independent CPS and CPPS objects through IIoT to optimize, guide, track and report on the entire Industry 4.0 operation. In this way, the shop floor marketplace is visible, traceable and managed while the CPS and CPPS actors in it are autonomous.

So with Industry 4.0 you can have it both ways: a decentralized shop floor that goes through a modern physically centralized MES to provide coherent, in-context information. It’s a fantastic new balance.