A single-lane cantilever type ASRS system stores various sizes of composite moulds up to 6.5 metric tons in six levels. The longitudinal axis of storage is variable, to allow a volume optimized distribution of moulds on each level.

One omnidirectional flatbed tooling AGV, with a capacity of 6,5 metric tons, distributes moulds through different work centres of the plant. A high precision "Cup& Cone" system on the AGV and on appropriate floor stands provides positioning accuracy of the deposited load ±1 mm. The tooling AGV has automated load-identification, load size-recognition and adapts automatically the safety scanner range to the load size.

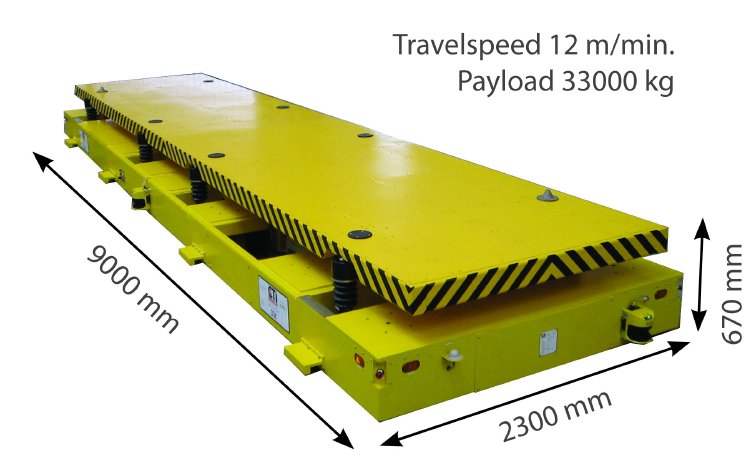

An omnidirectional flatbed autoclave AGV, with a carrying capacity of 33 metric tons transports racks with moulds to and from an autoclave oven. Both AGV types utilize a magnetic dot guided navigation system over concrete and steel flooring inside the autoclave.

The CTI WMS (Warehouse Management System) manages the warehouse contents, as well as the AGVs. The WMS linked to the customer's MES (Manufacturing Execution System) and stationary automation with specific interfaces to work centres manage the client's production process.