A variety of different woods are used in the manufacturing of guitars. Which wood is being used, depends on the part of the guitar that is being made. Back, top, sides, neck or soundboard all have different requirements. Ebony, Indian rosewood, mahogany, and bubinga were popular choices for a long time. However, since 2017 the import of tropical woods has been strictly regulated, posing a new challenge for the music industry.

Innovative solutions at HANIKA guitars in Baiersdorf

The Franconian guitar manufacturer HANIKA developed an innovative process that allows native woods to be used in the making of guitars.

(Guitars)

At HANIKA craftsmanship is regarded as tailor-made precision and sound as art. That is why guitars from the famous workshops in Baiersdorf symbolize quality and the tradition of craftsmanship. In conjunction with its trendsetting innovations, it has constituted the foundation for the company's success since 1953.

The guitar-manufacturing workshops at HANIKA are home to an experienced and highly qualified team of craftspeople, who with keen sensitivity and decades of experience build unmistakable and unique instruments. These instruments are build mainly by hand and are available both as a variety of different sophisticated types as well as personalized versions manufactured at the ‘HANIKA Custom Shop’ to meet the needs of every single guitar player.

For the development of concert guitars made from 100% native, thermo-modified woods HANIKA GITARRENBAU, in cooperation with the Technical University of Dresden, was honored as „ZIM craftsmanship project of the year“ by the Federal Ministry for Economic Affairs and Energy (BMWi) in Berlin, 2019.

With sustainability becoming increasingly important, new individual bridges of native wood are needed. Due to small batch sizes, all bridges have to be manufactured in-house. This cannot be done economically using traditional manual work, as many different varieties with different drilling patterns are required. Here, „Rhinoceros“ and „BobCAM“ can be used efficiently.

(Figure 1 Wood storage)

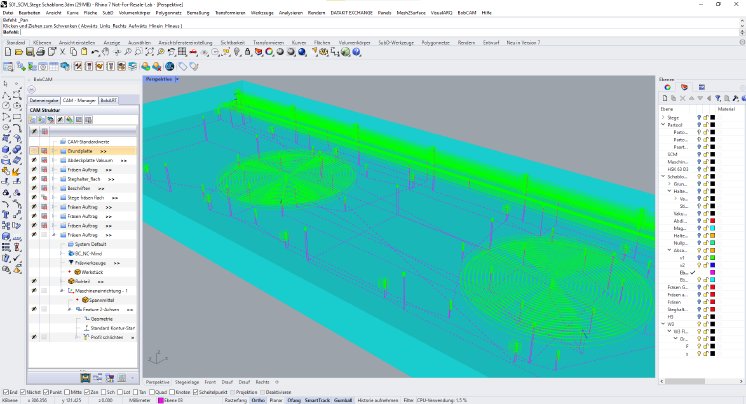

For many years, HANIKA GITARRENBAU has been using several CNC milling machinesin areas where technical precision and reproducibility are essential. „Rhinoceros“ and „BobCAM“ were incorporated from the beginning. They assist in making all necessary drawings as well as creating programs for templates, guitar necks, milling the back and top of a guitar and much more. Models for 3D printing are also developed with „Rhinoceros“ and „BobCAM“.

(Figure 2 5-axis machines ; Figure 3 Milling of a guitar neck ; Figure 4 Milling of a guitar head)

The making of guitars is an art that requires both craftsmanship and the use of machinery. While the use of machines has allowed luthiers to automate processes and work more accurately, ultimately it is craftsmanship that makes a quality guitar.

(Figure 5 Gluing of blocks ; Figure 6 Armin + Tobias Hanika winding edges)

Following their last award-winning project with TU Dresden, the challenge to construct individual guitar bridges from thermally modified domestic woods was waiting ahead. Again, the tried and tested „Rhinoceros“ software could be used to create fitting 3D models.

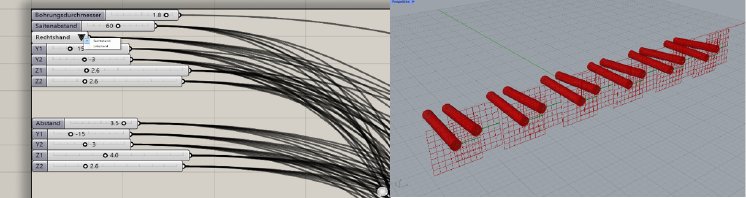

„Grasshopper“ is a graphical algorithm editor integrated in Rhino with which drilling patterns can be parameterized - easy and labour-saving. Small changes and individual requests can be implemented quickly.

Unlike other programming languages, Grasshopper requires no prior programming or scripting knowledge. Rather, it allows developers and designers to create form-generating algorithms without having to write code.

(Figure 7 Grashopper and calculation results in Rhino)

Due to individually adaptable post-processors, the „BobCAM for Rhino“ plugin can assist in programs being effortlessly created directly from the 3D model for different machines.

(Figure 8 BobCAM for Rhino)

Adapting the post-processor for a 5-axis machine requires a thorough knowledge of the machine, its kinematics and capabilities.

„BobCAM for Rhino“ provides extensive support for this customization. There is a wide range of predefined post-processors for different machine types. In order to meet a machine's specific needs, „BobCAM for Rhino“ offers the ability to create and customize post-processors. The software is intuitive and easy to use, facilitating and accelerating post-processor customization.

When choosing a CAD/CAM software, the quality of support is a crucial factor. Especially for complex tasks such as post-processor customization for 5-axis machines. „BobCAM for Rhino“ provides excellent support including an extensive knowledge database, video tutorials, online-forums and direct technical support which answers any questions quickly and competently.

The bridges designed with „ Rhinoceros“ are programmed in „BobCAM for Rhino“ and then processed one by one on a 3-axis and 5-axis CNC machine.

(Figure 9 Pre-milling with 3-axis-CNC, final processing of 5-axis-CNC)

At HANIKA, innovation and development of guitars have constituted the foundation of their success since 1953.

An inverted bridge, different designs for tops, a special monitor hole with a profile-milled edge as well as the various openwork heads are selected examples of the company's innovative strength.

(Figure 10 HANIKA 1a-custom-yew (based on HANIKA 1a-double-top) )

Information:

HANIKA Gitarren

Egerstraße 12a

91083 Baiersdorf

https://www.hanika.de

DataCAD Software & Service GmbH

Gutlay 4

55545 Bad Kreuznach

https://www.bobcad-europe.com

https://www.datacad.de

The text as a Word file and the images can be downloaded here:

https://datacad.de/...