The company was founded in 1888 under the name "Deutsche Automat-Pumpen-Fabrik".

In addition to various cast products, the range of services includes model making and contract manufacturing, mainly pumps and, in particular, retrofitting (which means modernization and optimization of existing systems ) and reengineering.

A current practical example of reengineering:

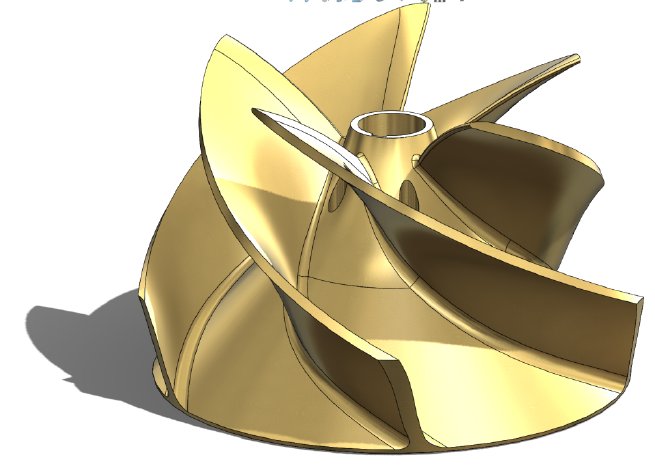

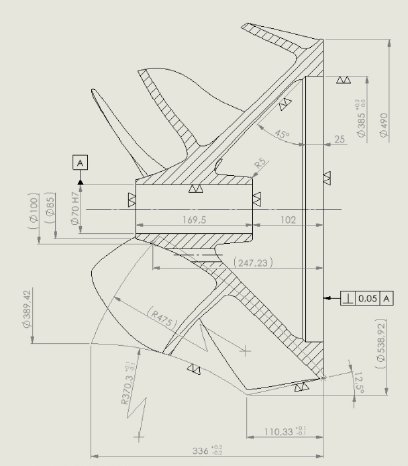

The accident of a pump - collision of the impeller with the wear plate – left 70 KG of undocumented gunmetal, because there were no drawings, production documents, or even CAD models for the ancient part.

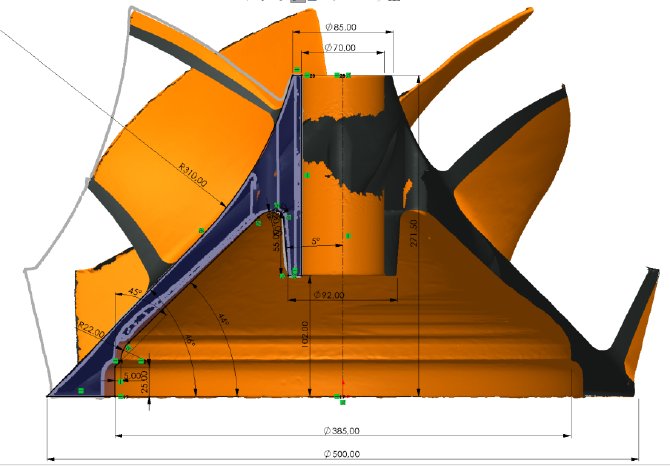

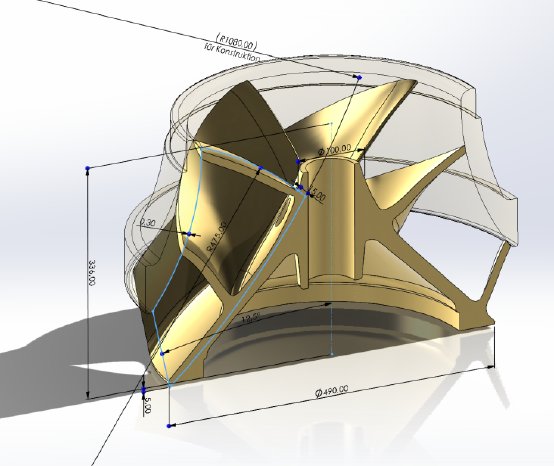

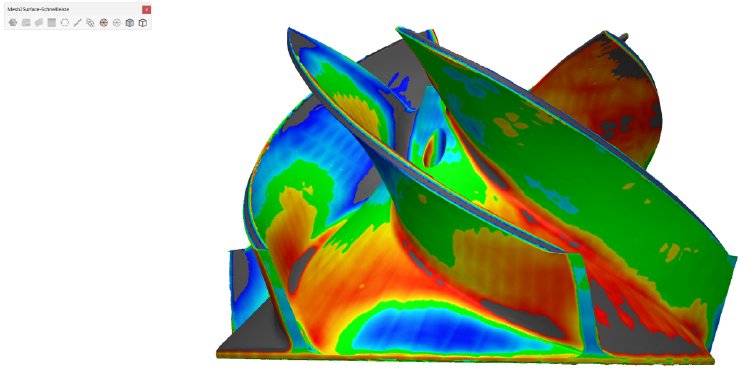

For the production of the urgently needed replacement impeller, the defective part was first scanned and the resulting mesh model was converted into a production-relevant 3D model with Mesh2Surface for Solidworks.

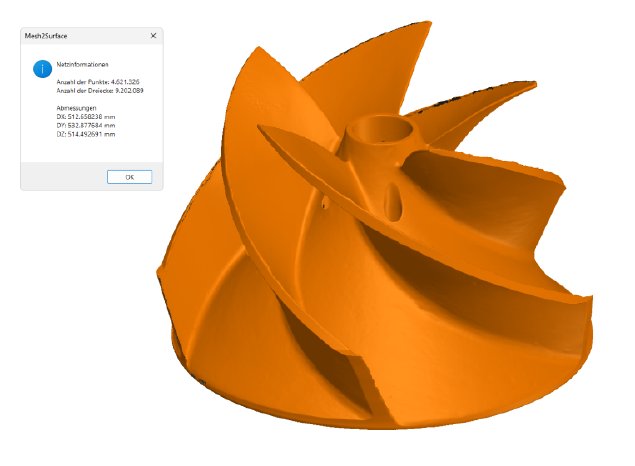

For reengineering, PME uses Mesh2Surface for Solidworks, a reverse engineering add-in for Solidworks that converts 3D scan meshes into CAD models. Mesh2Surface offers efficient tools to generate surfaces and curves to support the reconstruction of a professional CAD model.

The impeller was scanned with 0.5 mm point spacing. Result: 9 million triangles, 450 MB data set -> With Mesh2Surface, the amount of data was reduced by 50% with sufficient accuracy.

The exact reconstruction and additional optimization of the impeller based on the damaged parts was possible in a short time with the use of Mesh2Surface for SolidWorks. Conventional measuring techniques such as calipers or coordinate measuring machines would have provided only incomplete data to describe the complex 3D model.

PME Pumpen- und Modelltechnik GmbH Erfurt

Kalkreiße 13

99085 Erfurt

www.pme-erfurt.com

Tel.: +49 (0) 361 / 77958-0

Fax: +49 (0) 361 / 77958-33

E-mail: info@pme-erfurt.com