The measuring device manufacturer DataPhysics Instruments has expanded its product portfolio with the Portable Contact Angle Goniometer PCA 200. The PCA 200 is a compact, autonomous measuring device that determines contact angles and surface energy at the touch of a button. ‘The PCA 200 is a significant addition to our portfolio,’ says Sebastian Schaubach, Chief Innovation Manager at DataPhysics Instruments. ‘With the PCA 200, we can now offer a handheld device. Its compact design makes it the perfect companion for quality control of solid surfaces in production and incoming goods inspection.’

Alternative to Test Inks: Quantitative Analyses of Surfaces

The measurement of surface energy has been established for characterising the surface chemical properties of a workpiece. The surface energy describes how easily a solid surface can be wetted. In the production and quality control of surfaces, so-called test inks are often used for such wettability tests. However, with the help of these test inks, the wetting properties of solid surfaces can only be assessed subjectively.

With the PCA 200 Portable Contact Angle Goniometer, the surface energy can be precisely determined using contact angle measurements with two test liquids. This measurement offers significant advantages over test inks: the procedure is objective, quantitative, reproducible and provides additional information, as the surface energy is divided into polar and disperse components. This allows conclusions about whether the surface can be better wetted with aqueous or oil-based liquids, or how well a material can adhere to the surface.

Non-Destructive Testing of Large Surfaces Directly On-Site

In production and quality control, traditional laboratory measuring devices for precise, quantitative characterisation of surfaces reach their limits, as manufacturing parts are often too large and heavy.

This highlights another benefit of the PCA 200 Portable Contact Angle Goniometer: thanks to its compact design, it can determine the surface energy on large surfaces in a non-destructive manner. Thus, production parts such as car windshields, car body parts, large wafers or composite materials can be returned to production without being damaged after measurement with the PCA 200 and simple cleaning.

Fits in Every Pocket: Autonomous Measuring Device for Determining Surface Energy

The PCA 200 is completely autonomous and can be used wirelessly. With a powerful rechargeable battery, it is well-equipped for a working day. In addition, each filling of the liquid cartridges is sufficient for over 1,000 measurements. Prior to measurement, the PCA 200 provides a live preview image of the surface on its integrated touchscreen display. This function allows a visual check to ensure that the measurement is being taken in exactly the right place.

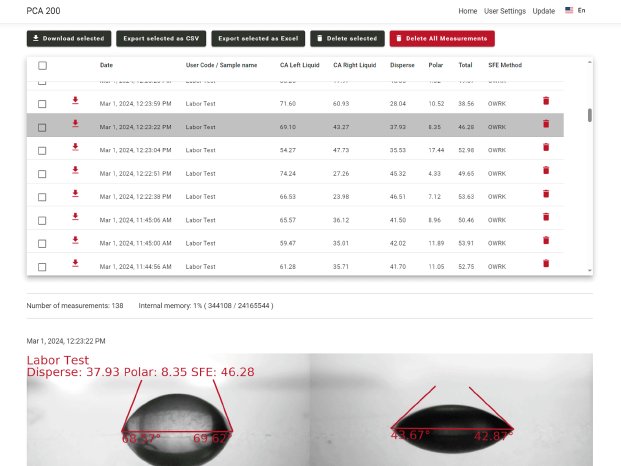

The PCA 200 simultaneously dispenses both test liquids onto the surface. This makes it possible to determine the surface energy by pressing a single button, which increases the efficiency of work processes. After the measurement, the device displays the measurement results on the screen in a matter of seconds. This enables immediate evaluations of the coating quality or sample purity right at the production site. Sample identification is facilitated by the integrated barcode/QR code scanner or a numeric keypad on the touchscreen. Additionally, the device can be easily connected to a PC via a USB-C port. On a clear user interface, accessible in any common web browser, device settings can be adjusted, and measurement results can be exported. DataPhysics Instruments also offers the expert software dpiMAX, a perfect complement for advanced analyses and systematic data management.

Background: Surface Energy in Detail

The surface energy makes it possible to precisely characterise the wetting behaviour of a solid surface. A higher surface energy generally indicates better wetting and better adhesion. A high surface energy also indicates that the surface is well cleaned and free of grease, for example. Drops of liquid typically spread on such surfaces. Glass, ceramics and many metals are examples of materials whose surfaces naturally have a high surface energy.

A low surface energy indicates poor wetting and poorer adhesion. Drops of liquid lie spherically on such surfaces. Many plastics originally have a low surface energy before they are ‘activated’. Depending on the area of application, a high or low surface energy is desirable. Materials are easier to print on or stick to if they have a high surface energy. Bathroom ceramics or windscreens, on the other hand, should have the lowest possible surface energy so that liquid drops can roll off easily.