Among other things, DATRON will be presenting “DATRON next” on all machines, a groundbreaking control software that has been continuously developed since its market launch in 2016. DATRON next enables both beginners and professionals to operate their milling and, more recently, dispensing machines easily and safely.

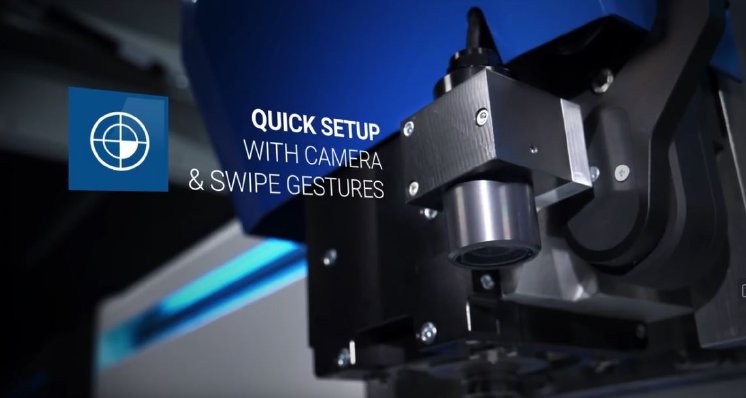

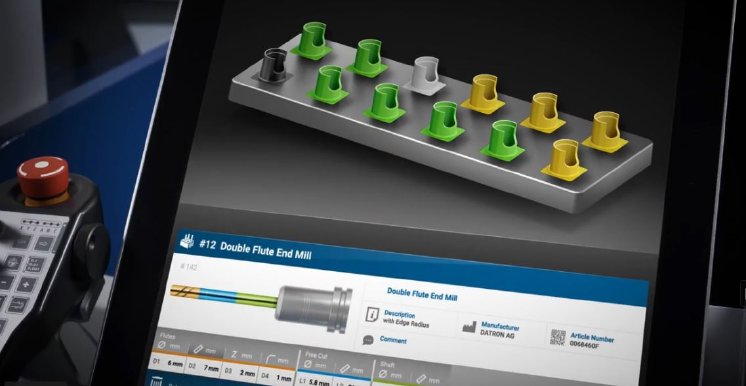

The pioneering DATRON next user interface allows intuitive control via swipe gestures and makes the DATRON machines of the current model generations almost as easy to operate as a smartphone. Thanks to the integrated camera and multi-touch display, users can capture their workpieces in a matter of seconds, without complex numerical input. The software offers further simplifications such as the option of simulating machining processes in 3D and correcting them in advance if necessary.

For experienced users, “DATRON next” offers comprehensive functions for adjusting machining parameters and supports the creation of complex programs. This combination of user-friendliness and performance sets standards in the field of high-speed milling and dispensing.

DATRON next 3.3 - Easier and more efficient milling

DATRON's continued innovative strength is particularly evident in the evolution of the DATRON next machine control. Release 3.3 has now been rolled out for the user community. It impresses with additional new features such as automatic switch-off, easier editing and program templates.

Sustainable: Switch off vacuum and shut down computer after program execution

The already extremely energy-efficient DATRON machines now allow even more, you can save even more energy by specifying directly in the execution options that the vacuum should be deactivated at the end of the program. There is also the option to shut down the computer automatically.

The shortest way to the goal: Inserting file paths in the editor

DATRON next's editor toolbox now allows you to insert the path of a file in SimPL syntax directly into the source code using the new “Insert file path” function. Alternatively, the file path can also be copied to the clipboard first.

Template help: Program templates when creating new programs

When creating a new program, DATRON next Release 3.3 now displays a list of all possible templates that can be used as the basis for the new program.

Trade visitors can experience further exciting details at the DATRON AMB stand in Stuttgart.

The complete exhibition program and the possibility to request free trade fair tickets are available at https://www.datron.de/de/events/amb.