Up to now, the prevailing opinion was that the destruction of data carriers should be done in the same way as with the destruction of information recorded on paper, namely by shredding it. Accordingly, there is a wide range of devices on the market that shred media into small pieces, punch holes or break them – and many users are convinced that such physical fragmentation of media guarantees the effectiveness of the data destruction process. Unfortunately, this method of destroying data is not completely secure. Some data can be recovered from damaged media. It's not easy, but it's possible. There are many reputable companies and authorities, but unfortunately also people with criminal energy who can recover data from shredded media, even if they have been cut into the smallest pieces.

Data destruction by magnetic field or brute force

An interesting alternative to such a brute procedure for destroying data on magnetic media, which also promises maximum security, are so-called degaussers (demagnetizers). Their functional principle is very simple: Let's imagine that the surface of a hard disk is covered with countless very small magnets. Each magnet has two poles - N (North Pole) and S (South Pole). When data is written on the disk, the poles line up according to the order of the bits (digital ones and zeros) that make up the data, such as a text file or a photograph. The process of degaussing now aims to change the magnetization along the surface of the platter in such a way that all the magnetic poles are randomly arranged. A degausser achieves this for a fraction of a second, which affects the hard drive. In addition, servo paths and disk calibration information are destroyed. As a result, the hard drive cannot be reused, and all data previously stored on it is irretrievably deleted.

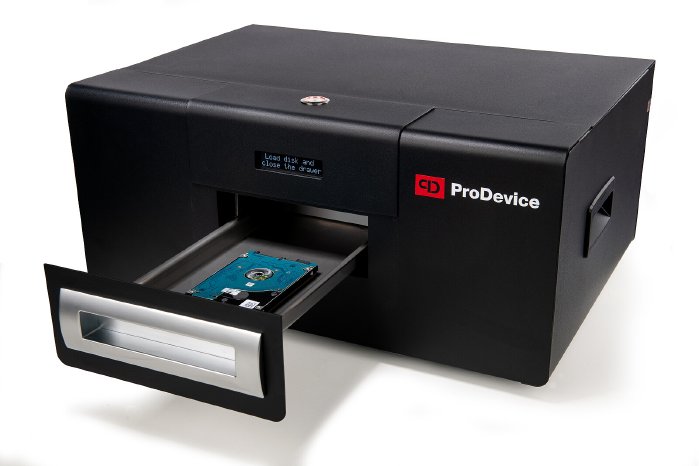

The whole process takes just five seconds using a high-end degausser device like ProDevice's ASM240, which is available from data center optimizer Daxten. Exactly as required by data protection law, the destruction is fully automatically documented as an image and video using integrated functions. Whereas with shredding, every single step of the destruction must be recorded, photographed, filmed and logged manually by the staff.

Space-saving, flexible and health-friendly

Degaussers score big because they work quietly and, unlike shredders, do not produce enormous noise and sharp-edged small parts or emit dust and the pollutants it contains. And last but not least, degaussers with the footprint of typical office equipment are very compact, space-saving and can be used flexibly at different locations - especially when you compare them with automatic shredders, which often reach dimensions that are more familiar from high-performance copy machines, and with weights between 500 and over 1000 kilograms cannot exactly be described as handy and mobile.

Recyclability for sustainable and resource-saving data destruction

Electrical and electronic waste equipment and associated components, which of course also include magnetic data carriers, cause one of the fastest growing waste mountains in Europe. A declared goal is to recover treasures such as rare earth elements or permanent magnets from this via recycling processes, because Europe is dependent on the import of these materials and raw materials, as there are currently no marketable substitutes available. The higher the recovery rate of these materials during recycling, the greater the reduction in dependence on exporting third countries and their maximum price policy. Retrieving the valuable materials from degaussed but physically undamaged media is of course incomparably easier, more effective and more productive than from shredded, broken or otherwise destroyed magnetic media carriers.

Further information on ProDevice's degausser technology and product solutions is available from Daxten at www.daxten.com/uk/, +44 (0)20 8991 6200 or info.uk@daxten.com.