The conversion to a student residence turned it into one- and tow-person apartments with their own bathrooms and kitchen pantries, as well as into shared apartments for 3 people with shared kitchens and baths. A new flight of stairs was added to the semicircular interior stairway to develop the attic storey. The new roof glazing with smoke and heat exhaust provides daylight to the stairway. Under the roof glazing hangs an accessible revision level with 4 x 4-square fields with expanded metal inlays, similar to an illuminated ceiling.

Highlighting the renovation work is the 75 square meters large roof terrace, on the yard side.The beams under the existing flat roof were spread in cross-section of 16 on 16 cm with a centre distance spacing of 80 cm. The flat roof was structurally only designed for a snow load of 0.75 kN/m².Due to the encountered actual state, Mr. Vorrink, the architect, together with the statisticians Mr. Wroblewski had to think of something very special.

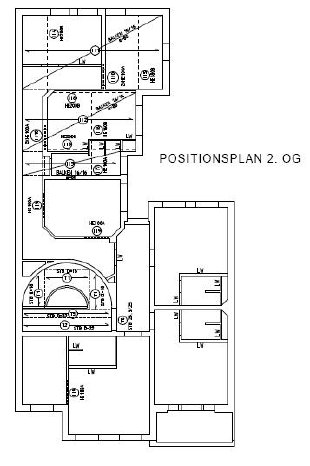

The field lengths of the wooden beams were reduced by five steel joists S 235, to effectively shrink the field sizes and thus the deflection. The largest span was bridged with a 4.90 meter-long steel beam (position plan P1, 3rd floor, position 114).

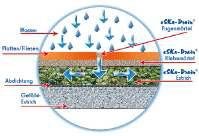

The high steel prices and goal of minimizing the bearing- pressure and dead weight led to the optimization of the T-joist-measurements.The structural improvement was made possible by the specific roof terrace construction, whose central element is the light drainage screed eSKa-Drain-Light. Its net weight is only 200 kg / m³. The new roof top terrace was built on top of the old, intact seal sheeting:

- Separation and protection layer with a weight of 200g/m².

- To offset the incline the resin bonded drainage screed, from 5 to 27 cm, was applied and the surface horizontally smoothed as a plan- parallel substructure.

- Terrace panels in the dimensions of 40 x 40 x 3 cm have been glued on to the light weight screed, as top layer.

- The separation to the gravel margin was done by using expanded glass granule screed.

Because of these constructive enhancements the dead weights could be limited to 2.2 kN /m². The roof terrace is designed for traffic loads up to 3.5 kN /m².

Due to the heated area under the roof terrace the energy efficiency quotient was important as well.

The insulation properties of the new roof terrace layout consists of:

- Leveling layer eSKa Drain-Light - in the middle d = 10 cm.

- Existing insulation from an earlier roof renovation d = 10 cm.

- New insulation between the wooden beams 16/16

- d = 16 cm.

From this roof terrace layout results a U-value of 0.13 W/m²/ K.

Resin instead of cement Resin as a binder and Poraver as an aggregate make the drainage level multifunctional. It is free of cement and frost proof. Lime blooms are surely prevented and frost damage is a thing of the past. The matrix is characterized by an easily applied, homogeneous screed layer.

In addition, the advantage is that the matrix system prevents the usually high water vapor pressure under the surface.

The special material properties of Poraver reduce the net weight of the balconies, terraces and flat roof structures considerably. Furthermore, the use of Poraver guarantees an effective thermal insulation, which reliably protects the space from heat loss in the winter and heat build up in the summer.

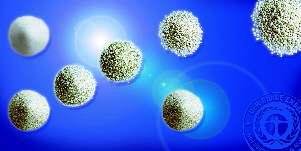

Recycled glass as aggregate

By incorporating Poraver into the screed layer perfect thermal insulation qualities are achieved. At the same time, this structural property is an additional protection against the replacement of tiles or panels due to rapid temperature changes. In addition, Poraver makes an active contribution to noise protection. Due to the extremely low net weight - 1m³ expanded glass granules weigh only about 200 kg - the use of Poraver entails a strong reduction of the entire building mass and allows for open spaces, where otherwise inaccessible areas would be.

Poraver is 100% recycled glass that is produced by the Dennert Poraver GmbH in Schlüsselfeld in a special procedure ground to fine dust , processed, granulated and expanded into small creamy white pearls. It enhances the drainage system eSKa - Drain not only by its striking structural properties but also with its absolute environmental purity.

What makes the light weight aggregate Poraver so popular.

Poraver is the ecologically rewarded light weight aggregate from 100% recycled glass. It is produced in a special procedure. The round granulate is used in top quality free of broken granule particles in diameters of microscopic 0.04 to 16 mm.The Poraver benefits include very low weight with high compressive strength, excellent heat insulation and sound absorption properties and Alkali resistance. In addition, Poraver is non-flammable, does not provide a breeding ground for bacteria and prevents, thanks to its amorphous glass structure, Silicosis. These seamless quality features make Poraver the best light weight aggregate.