Cleaning and filtration systems, cooling water circuits and cooling towers, heating and ventilation systems and other process equipment, as well as water supply systems, need to supply liquids or gaseous media based on demand. Since such systems have very long service lives, they are usually designed with sufficient spare capacities so that they can be adapted to future requirements, like changes in delivery rate and delivery pressure. Such oversizing, however, causes unnecessarily high operating costs and energy wastage because these systems are often operated with only coarse control.

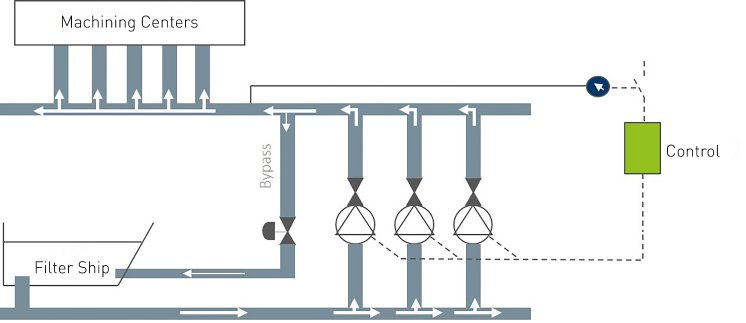

This is illustrated by the example of a central cooling lubricant supply system. If the pressure set for the fluid supply is exceeded or undercut, a pump is switched on or off, respectively. If the system is fitted with four pumps, for example, the pressure is controlled in 25 percent increments. The excess volume of coolant supplied is then fed back unused into the filter system via a bypass line and the energy used for it is completely wasted.

Accurate, demand-based control with Ecoclean DFC

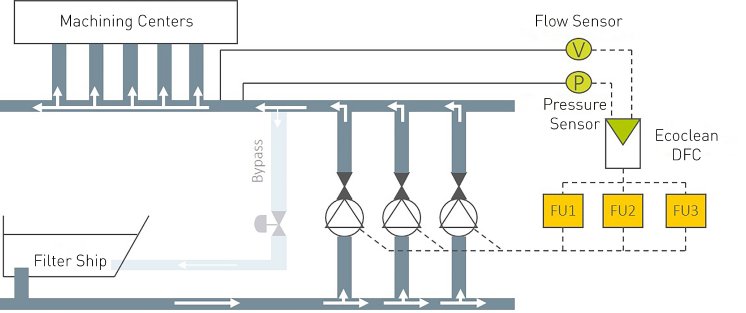

Due to this coarse control, the systems not only consume significantly more energy than required but also emit correspondingly high levels of CO2. This is where the Ecoclean DFC dynamic volumetric flow control developed by Ecoclean comes into play. Based on the measured variables of pressure and volumetric flow, the pumps or fluid systems can be controlled precisely and quickly as required. Measuring sensors are integrated into the main outlet of the process system and the pumps are equipped with variable frequency drive units. The pump speed can be so finely controlled by the Ecoclean DFC that the amount of coolant delivered is automatically and quickly adapted to the current fluid requirement at any time. This makes the bypass lines completely superfluous. What is much more important, however, is that only the amount of energy actually required is consumed, thus significantly reducing not only operating costs but also CO2 emissions. This highly efficient pump control enables energy consumption to be cut by anything up 45 percent. As a result, federal, state and local government funding programs generally subsidize the investment costs for retrofitting existing supply systems with Ecoclean's dynamic volumetric flow control by 30 percent.

Fast amortization due to high energy savings

One of the projects realized so far in this field is the central supply system for cooling lubricant at the Bosch Rexroth AG plant in Horb. Before integrating the Ecoclean DFC control system, the annual power consumption was around 256 MWh with CO2 emissions amounting to approximately 135 metric tons. A saving potential analysis carried out by Ecoclean showed that the demand-dependent control of the system’s pumps with DFC could result in energy savings of around 35 percent. In fact, the consumption figures recorded after installation of the DFC control system revealed that power consumption actually fell by 40 percent (103 MWh). This enabled CO2 emissions to be reduced by approximately 54 tons annually. Without taking any subsidies into account, the payback period for integrating the dynamic volumetric flow control was only about two years.

The example demonstrates that, by controlling fluid quantities in line with demand, a marked decrease in operating costs can be achieved with comparatively manageable investments. And this combined with a corresponding contribution to the conservation of resources and reduction of CO2 emissions.