In automotive manufacturing and its supplier industries, mechanical engineering, aerospace applications, precision and micro-mechanics, medical and optical systems, electronics and other fields of industry, component parts are subjected to cleaning in order to prevent quality problems in downstream processes and to ensure flawless product performance. In recent years, the focus in many industries lay on removing particulate contaminants. However, given new or modified production, joining and coating technologies as well as improved materials and combinations thereof, the elimination of film-type residue – e.g., of machining and preserving media, release agents, silicones, other auxiliary production compounds, or even fingerprints – is gaining increasingly in importance. This is because such residue can impair the quality of subsequent processes, e.g., coating, welding, adhesive bonding, sealing, painting or heat treatment. Ecoclean (formerly Dürr Ecoclean) addresses these evolving requirements with a number of new solutions.

Ultra-fine degreasing by a combination cleaning process with integrated low-pressure plasma treatment

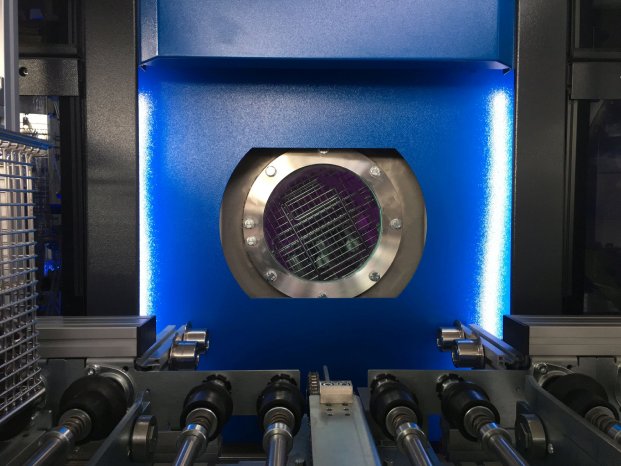

For workpieces made of steel, aluminum, glass, ceramics and some other materials that are cleaned in batch processes – whether in bulk or arranged in part carriers – the company has developed a combination cleaning technique merging wet chemical cleaning with a subsequent plasma cleaning step. To this end, a low-pressure plasma cleaning operation is integrated into the wet chemical cleaning line. Since virtually all components needed for this cleaning technology – e.g., vacuum, measuring and control equipment – are already in place in the manufacturer's wet chemical cleaning machines, the additional cost and engineering effort remains modest. The advantages of the integrated plasma cleaning process in ultra-fine degreasing are substantial, on the other hand, including a high operating flexibility, reduced process times, low investment and operating costs, plus very compact equipment build.

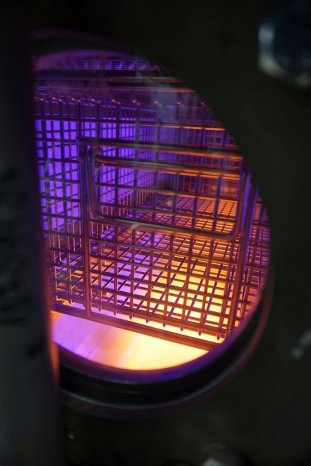

Cleaning is initially performed as usual by a solvent-based wet process, followed by vacuum drying of all workpieces. The work chamber is then rinsed and its internal pressure is reduced to less than 1 millibar, whereupon the process gas (e.g., filtered ambient air or oxygen) is introduced and the plasma is ignited. Due to excitation by the process gas, a plasma of high-energy ions and free electrons – plus other reactive particles – is thereby formed in the vacuum. Contaminants on the part surface, such as grease or oil residue, are chemically attacked and transformed into volatile compounds. At the same time, the plasma's UV radiation likewise exercises a cleaning effect, e.g., by breaking down long-chain hydrocarbons. The gaseous decomposition products of the plasma treatment are extracted from the work chamber by suction. Thanks to the combination wet-process and plasma cleaning operation, the free surface energy that is key to achieving an optimum adhesion strength can be raised to 50 to 80 mN/m in one single process step.

Integration of different pretreatment methods into one system

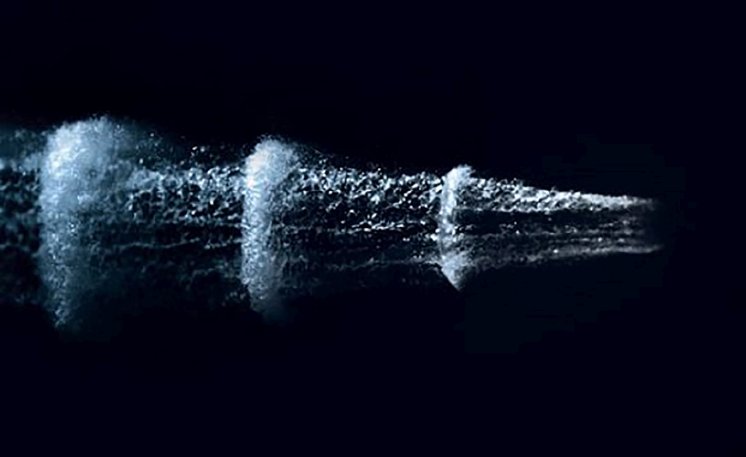

The partial or full-surface cleaning and activation – and, in part, coating – of individual metal or plastic products is central in the expansion of Ecoclean's process portfolio. For these diverse objectives, compact application systems were developed for integration into a host of requirement-focused equipment concepts. Each system can be fitted with different treatment technologies such as atmospheric pressure plasma, EcoCsteam, laser, CO2 snow blasting or EcoCbooster processes, whether configured as an automated standalone unit or integrated into a production line. The company's aim is to solve each of the various surface treatment requirements with the most technically and economically beneficial technology. Thus, the use of the new Disc-Jet atmospheric pressure plasma source developed by the Fraunhofer Institute for Surface Engineering and Thin Films (IST) permits laminar and contoured as well as depth processing. Due to the so-called "cold" surface discharge (30 to 60°C), even temperature-sensitive substrates can be treated in this manner. An atmospheric pressure plasma, for instance, allows part surfaces to be selectively fine-cleaned, activated and coated with an adhesion promoting agent. Where the surface is to be textured as well as cleaned, laser treatment is the method of choice, depending on the given material. EcoCbooster technology provides a pretreatment method for the selective, effective and efficient activation of surfaces prior to, e.g., thermal spraying. The automation system, too, is perfectly adapted to the specific requirements and application situation. Thus, robot-based solutions can be realized just as readily as multi-articulated handling systems and CNC linear drive units. Across all variants, either the workpiece, the tool or both can be moved to match the given task definition. Thanks to this high flexibility, the new surface treatment toolkit is the perfect solution for diverse applications in electromobility, medical equipment technology and numerous other fields of industry.