According to Gartner, digital supply chain twins form the foundation for end-to-end digitized supply chain planning. Gartner had already described this as a key technology in its "Top 8 Supply Chain Technologies 2019"2. Christian Titze, Gartner VP and Research Director for Supply Chain Management, is convinced: "Digital supply chain twins are inevitable as the digital world and physical world continue to merge." The Digital Supply Chain Twin is the integrated digital representation of all relationships between the physical units of the process chain from supplier to recycling. The goal is to fully map and link products, processes, customers, markets, distribution centers, production, finance and external data.

Digital supply chain twins are at the heart of the supply chain

Benoit Lheureux, Research Vice President at Gartner, had confirmed in an article in early 20193 that Digital Twins had meanwhile arrived in the mainstream of companies. One of the most compelling reasons, he says, is that Digital Twins create tangible value for businesses: "We see digital twin adoption in all kinds of organisations," Benoit Lheureux is cited. This demonstrates another advantage of the technology. Digital Twins break with the silo thinking and siloed actions prevalent in many companies. In at least 30% of all companies, a Digital Twin would be used by several departments. "These findings show that digital twins serve a wide range of business objectives," says Lheureux. "Designers of digital twins should keep in mind that they will probably need to accommodate multiple data consumers and provide appropriate data access points."

The eccenca Knowledge Graph platform Corporate Memory addresses this need. According to Lheureux, true integration is often still very complicated. In most cases, data from different applications and silos can only be integrated with difficulty or not at all. The reason for this lies in the established data management concepts based on locally limited relational databases (application centricity). The ydon't match with a global supply chain, where data from various sources and contexts must be integrated and managed in a way that is comprehensible to all users (data centricity).

"Gartner has correctly judged the role of the digital supply chain twin. It is the heart of a digital supply chain and the basis for comprehensive predictive analytics," confirms Hans-Christian Brockmann, CEO of eccenca. "However, Gartner is right to warn that many supply chain planning providers are filling old wine into new tubes. Most solutions still use static data models, into which the dynamic data is forced. However, we want to give our customers a real insight into the supply chain processes. The supply chain data therefore determines the data model - and not the other way round. Instead of forcing our clients into application-centric corsets, we deliver a data-centric architecture. This architecture takes into account their requirements for company-specific processes and models as well as for flexible adaptation. This enables our clients to achieve what Gartner defines as an ideal: a dynamic data model that describes the entire supply chain from start to finish. I think that's why Gartner explicitly mentions us in their report."

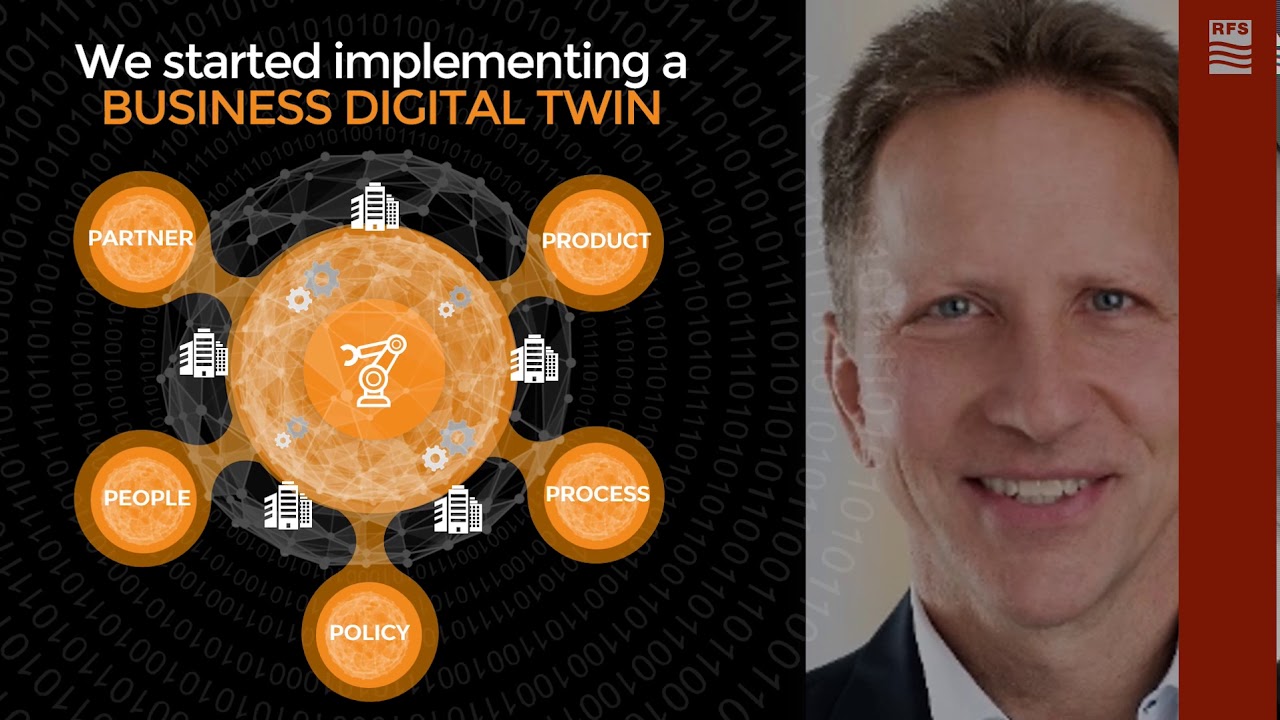

eccenca does not use static, relational data management concepts to set up a digital supply chain twin, but its knowledge graph platform Corporate Memory. This enables the free linking, enrichment and integration of distributed data. The platform forms the foundation for building the digital supply chain twin in a company. This enables access to data independent of application silos via the entire supply chain if required. The digital twin then digitizes and links all relevant data and context information on products, processes, policies and business structures (e.g. partner ecosystem) as well as the implicit knowledge of the respective experts in the workforce. This results in a high degree of data transparency and data centricity that go beyond data silos. Implicit knowledge of the respective data, process steps and internal regulations is made explicit via the Knowledge Graph. A wide variety of data sources can be flexibly integrated. The Software Developer Kit also gives customers the freedom to independently extend the platform to other use cases.

This gives companies maximum freedom of choice and transparency in an ever faster and more complex supply chain.

More information about the Knowledge Graph platform eccenca Corporate Memory can be found at: https://www.eccenca.com/en/products/eccenca-corporate-memory.html

Gartner Disclaimer

Gartner does not endorse any vendor, product or service depicted in its research publications, and does not advise technology users to select only those vendors with the highest ratings or other designation. Gartner research publications consist of the opinions of Gartner's research organization and should not be constructed as statements of fact. Gartner disclaims all warranties, expressed or implied, with respect to this research, including any warranties of merchantability or fitness for a particular purpose.

Gartner Resources

1Cool Vendors in Intelligent Supply Chain Execution Technologies, Gartner, September 4, 2018 (available to Gartner subscribers)

2Top 8 Supply Chain Technologies 2019", Gartner, April 24, 2019

3Gartner: digital twins beginning to enter the mainstream, Information Age, February 20, 2019

Hype Cycle for Supply Chain Planning Technologies 2019, Gartner, October 29, 2019 (available to Gartner subscribers)