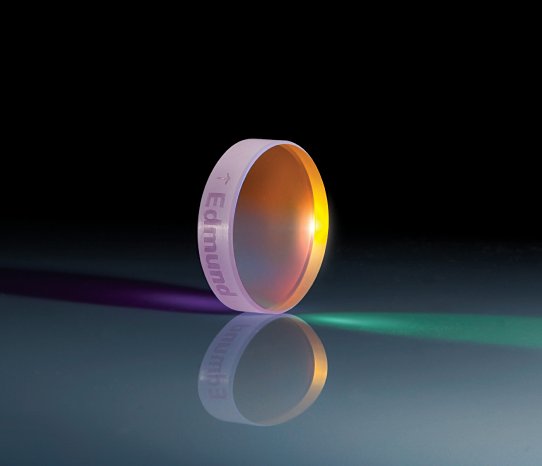

Lot-traceable coatings documented in individual Certificate of Compliance

Each Laser Mirror is individually packaged with its own Certificate of Compliance, including batch traceability to the exact mirror coating lot. These new high-performance IBS mirror coatings provide increased laser damage threshold and reflectance up to 99.9% at 45 degree incidence. Edmund Optics is also pleased to include laser engraved markings on each Laser Mirror, identifying the Edmund Optics stock number, design wavelength, and indicators pointing to the coated mirror surface.

Excellent thermal stability provided with fused silica substrates

These UV grade fused silica mirror substrates are polished on both sides, which allows a user to monitor transmitted light leakage through the backside in the most demanding laser applications. The mirror coated surface meets stringent λ/10 flatness (or surface accuracy) and 10-5 scratch-dig.

Twelve new Laser Mirror models include the YAG fundamental at 1064 nm, the second harmonic at 532 nm, and UV versions at 355 and 266 nm. Sizes are available in inch-scale formats of 0.5 (12.7 mm), 1.0 (25.4 mm) and 2.0 inch (50.8 mm) diameters.

TECHSPEC High Power Nd:YAG Laser Mirrors will be on display at the Edmund Optics Booth 409, Hall B1 at Laser World of Photonics in Munich, Germany from June 22-25.