TubeScan XL increases the productivity of printing and slitting machines by consistently providing the user with a complete overview of the current job in real time, including the precise amount of waste. This allows the machine to be stopped exactly when the job is completed. The presentation and interaction options can be grasped intuitively, allowing operators to master the system quickly and safely even without advanced computer skills.

Whatever the application, effective print inspection demands both high imaging performance from the system's optical components and intelligent image processing. This applies to reflective surfaces, embossing, security features, barcodes, and variable print data. Both of these features are combined in TubeScan XL, which has hardware that includes three matrix cameras, excellent lighting units, and convenient image reproduction on 32" monitors that can be operated intuitively even without advanced computer skills. The display also allows precise analysis of detailed areas using high-resolution zoom functions, while the LED stroboscope illumination ensures razor-sharp images with pleasingly low power consumption.

Sharp view with high-performance digital image processing

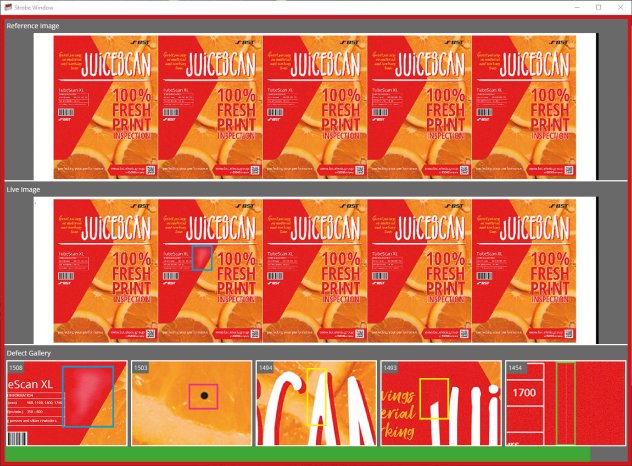

Efficient print inspection focuses on the parameters that are relevant for quality. That’s why TubeScan XL provides adjustable sensitivities for different defect classes, a masking function to omit definable areas, and an algorithm that has been specially optimized for text inspection. During text inspection, a master image is taken at the beginning and used as a reference to compare the current production images against. The detected defects are shown in real time on the HD monitor – a feature that is even available while the machine is still being set up. Color consistency can be ensured by monitoring the Delta E color difference.

TubeScan XL is available in printing or slitter configurations

The highest standards for printing inspection are met by TubeScan XL, which can be placed on standard printing and slitting equipment. The system is available in two different configurations depending on the area of application: For printing presses, high-resolution cameras with 7200 pixels offer great image quality. Additionally, while using TubeScan XL to inspect the web on a slitter, ultra-fast cameras ensure reliable and accurate defect detection. At maximum speeds of 800 m/min or 30 frames per second in live mode, TubeScan XL seamlessly displays every pattern repeat in real time. The stroboscopic effect allows the pattern repeat to be shown on the display, so defects can be detected immediately and easily by the operator.

The TubeScan XL series can be equipped with all TubeScan accessories and lighting options for comprehensive monitoring of the printing or finishing process. This includes incident light, transmitted light, contour light and UV illumination. The standard setup offers both dark field illumination for diffuse materials and bright field illumination for highly reflective materials. Integrated high-performance LEDs can be used to illuminate the web from behind in order to find the smallest of holes in opaque material. The optional contour light lighting unit can be used to emphasize the contours of wrinkles, bubbles or embossed patterns so that imperfections can be identified more effectively. In addition to this, the system is also available with UV lighting for inspecting luminescent areas such as coatings, adhesives or silicones. White light and UV light can be used in combination in this configuration.

Maximum yield thanks to QLink workflow

On slitters, QLink workflow creates a defect log for each individual daughter roll, which the doctoring machine uses as a basis for eliminating defects. The degree of tolerance is set as a rule during job setup, and defines what types of deviations from the master image are considered defects. The QLink Slitter categorizes the inspected material into “defect-free,” “waste” and “to be corrected” based on this rule. Relevant statistics for the daughter rolls are clearly displayed to the operator on the screen. TubeScan XL controls the bidirectional doctoring machine, where the documented defects are automatically placed in a predefined target position before being marked or eliminated. This ensures excellent quality control and maximum output.

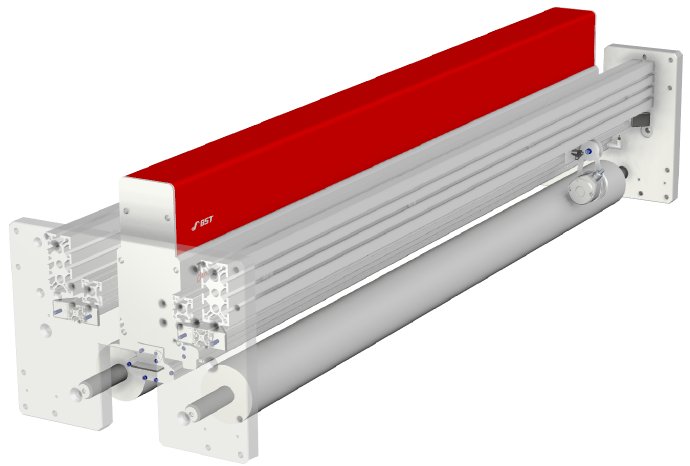

Robust mounting frame made of aluminum profiles

TubeScan XL has a universal mounting frame with two built-in deflection rollers. Depending on the desired web path, these deflection rollers and the encoder crossheads can be pre-assembled in different ways.

About BST

BST GmbH, an elexis Group company, is one of the leading suppliers of quality-assurance systems for web-processing industries. The company, which is based in Bielefeld, north-west Germany, offers solutions for web guiding, surface inspection, web monitoring, 100% inspection, color measurement, color management, register control and automation. The company has decades of practical experience in these areas, with installations for more than 15,000 customers all over the world in the printing and packaging, paper and film, rubber and tire, battery and fuel cell, and printed and organic electronics industries. BST stands for high-quality monitoring, smooth production processes and first-class service worldwide.

www.bst.elexis.group