The worldwide surge in hydrogen and fuel cells requires manufacuterers to swiftly transition to mass production scaling. Amidst transformative technologies, success hinges on cross-industry innovations as the cornerstone for established companies to maintain competitiveness within the fast-paced dynamics of global markets. Leveraging expertise attained from quality assurance in the battery and plastics industries, BST provides sophisticated products that enable fuel cell and electrolyzer manufacturers to achieve high quality production while reducing costs and waste. Absolute precision is essential when processing material webs for the production of fuel cells. BST rises to this challenge by offering high-performance inspection and web guiding systems renowned for their precision, extensive functionality and user-friendly nature. "Fuel cells are a key technology for decarbonizing the economy. We look forward to meeting today's and tomorrow's challenges in the production of fuel cell systems with our innovative products to further drive the expansion of sustainable energy systems," summarizes Johannes Scholz, New Business Development at BST.

Error Reduction and Human Relief with BST COATINGControl

BST COATINGControl stands as a prime example of applying comprehensive experience in measurement and control systems drawn from diverse industries. This solution positions the. company as a contender for the prestigious hy-fcell Innovation Award. The system combines intelligent control technology and precise measuring instruments with line scan or CIS camera technology. This approach mitigates the escalating dilemma between the industry's strict quality requirements and pricing demands, and the challenges posed by limited resources and a shortage of skilled personnel. "BST COATINGControl thus provides relief in an environment where even the smallest irregularities lead to rejects. The system controls itself with high-precision measurement technology and simultaneously optimizes the web-running processes with intelligent control technology. Control accuracy in the µ range is achieved thanks to robust edge detection via a central control unit and closed-loop image processing algorithms with the FRAMEGuide web guiding system," explains Scholz. Due to the consistently perfect coating positioning, further manual offset correction by the machine operator is not required. This interaction is particularly relevant for applications in the battery, fuel cell and printed electronics industries.

Elevated Precision with Minimal Stature: FRAMEGuide Pro

When precision in measurement is achieved, the control must follow suit in order to fully capitalize on the advantages. With its innovative engineered high-performance drive, the FRAMEGuide Pro web guiding system achieves unparalleled precision in guiding accuracy. With repeatability of ±10 μm, it ensures highly accurate control results in every application. Due to its minimal overall height and the alignment of fixed and moving frames at the same level, the FRAMEGuide Pro can be integrated into all machine layouts. The optional motorized sensor adjustment offers additional flexibility.

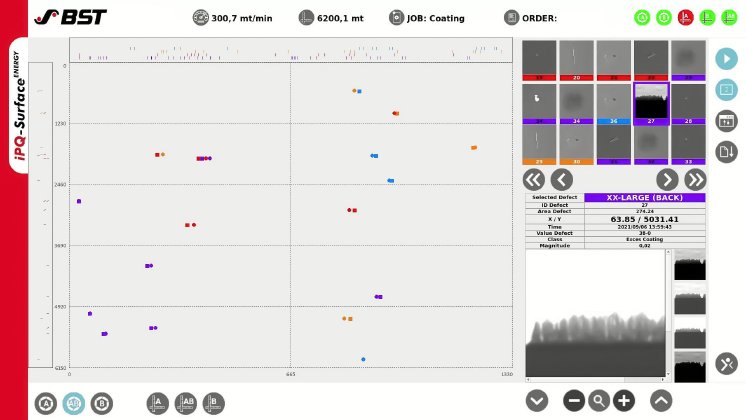

Advanced Surface Inspection: BST iPQ SurfaceENERGY

BST iPQ-SurfaceENERGY was specially designed to cater to surface inspection and measurement needs within battery cell production. Moreover, it plays a crucial role in the production of fuel cells by guaranteeing only defect-free material from processes like coating,is processed. The advanced surface inspection system consists of high-resolution cameras, multiplexed lighting and a software framework featuring multiple interfaces for seamless integration into Industry 4.0 environments. Other features include AI-based defect classification, position measurement, comprehensive quality documentation, and a clear display of all measurement results and defects. As a result, iPQSurfaceENERGY assists fuel cell manufacturers in optimizing production processes and overall plant efficiency, all the while ensuring 100% quality across different machines and systems.