EMG IMPOC covers a wide material spectrum from IF-steels, Dual Phase steels, TRIP steels and 3rd Generation AHSS Grades with tensile strength values up to 1600 MPa. The system can be applied at production speeds up to 900 m/min for material gauges up to 3 mm and for production speeds up to 600 m/min for thicker material up to 6 mm.

Application fields

If we look at the type of production lines for the use of EMG IMPOC, we see that in a good 60 % of cases they are hot-dip galvanising lines, approx. 20 % are annealing lines, almost 10 % are pickling lines (both push and continuous pickling) and the remaining 10 % are further processing lines.

If we analyse the use in hot-dip galvanising lines and other lines in more detail, a whole range of different value-adding factors come to light. The main ones are:

- reduction of destructive testing

- reduction of material losses and devaluations & minimising scrap

- reduction of costs for the use of inspection lines

- reduction of unnecessary packaging processes (depending on how long it takes for the results of sample tests to be available)

- higher yield and tremendous cost reduction in the development phase of new steel grades

- reduction of unnecessary further processing in downstream processes due to unsuitable material properties and,

- last but not least, a significantly lower rate of quality complaints and end customer claims.

But why is EMG IMPOC such a powerful tool for generating ROI?

As the reader may already know, EMG IMPOC does not allow a direct measurement of material properties (i.e. tensile strength and yield strength). The direct IMPOC measurement value is the gradient of residual magnetic field strength in A/m² on the top and bottom side of the steel strip (the so-called IMPOC raw value). Based on that raw value, the mechanical parameters of the steel strip (i.e. tensile strength and yield strength) can then be assigned to this gradient via correlations with the destructive testing results and mathematical modelling, taking into account the steel group, the strip thickness, the skin-pass rolling degree and the yield degree either in combination or separately.

Even without mathematical modelling EMG IMPOC delivers valuable data or the blind will be able to see

The IMPOC raw value can be produced over the entire strip length immediately after installation, thereby enabling a relative statement to be made regarding the material behaviour in the coil.

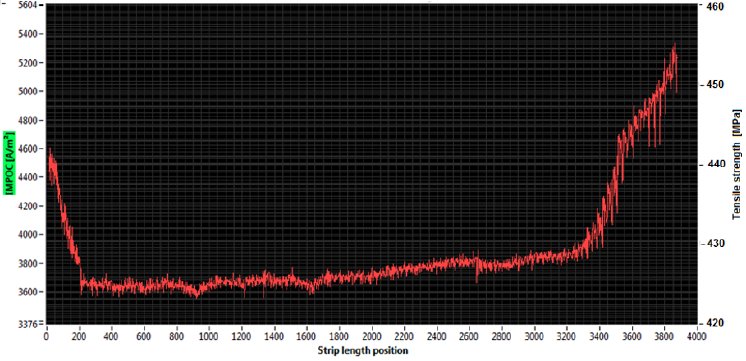

The image shows a typical curve for the IMPOC measurement raw value over the strip length.

In this graph the typical bathtub shape shows the influence of the different cooling scheme at the beginning and end of the strip due to the recoiling at the exit of the hot mill. The tension leveller degree is unchanged over that period. The variations over the strip length in this specific case are in the range of 10 %. This makes process drifts and even small deviations visible and allows appropriate and immediate reactions. Manufacturers do not have to wait for the results of destructive tests, which are only available hours later, and intensive destructive testing can be reduced; an invaluable asset in the development of new materials, especially for AHSS (Advanced High Strength Steels). The results are immediate, or in other words, "the previously blind will be able to see".

Process optimisation based on EMG IMPOC measurements in the pickling line

Pickling lines are the first element in the process chain to detect deviations from the desired material properties. A good number of users in pickling lines can manage with the above-described observation of relative changes in the IMPOC raw value, because destructive testing results aren’t (or in less quantity) available at pickling lines. For those who want to go a step further, EMG generated “standard coefficients” for regression models, which can be applied in pickling lines. Long term analysis showed that these “standard coefficients (EMG IMPOC express)” delivered absolute values for the tensile strength which differ from relative changes in full blown models only in the range of +-5 %. In the end the user gets a perfect overview of the relative changes of tensile strength over strip length and a good indication of the absolute values. Immediate reactions with respect to strip release and blocking or alarms concerning cooling problems in the hot mill are therefore a direct consequence of the EMG IMPOC application in pickling lines. Again, for this application no further model development is required and the user gets the results immediately after the system operation starts.

Finally

Of course, the exact monetary value of the EMG IMPOC application depends strongly on the specific application scenario for the selected production line. EMG offers several ways to support you in calculating your own possible ROI by implementing EMG IMPOC: EMG offers direct consulting and EMG IMPOC workshops with a standardised ROI calculation scheme for your direct support. If you are interested in the latter, please send a short, informal email to franziska.kneisel@emg-automation.com. We are happy to support you whenever and wherever you want, digitally or in on-site meetings.