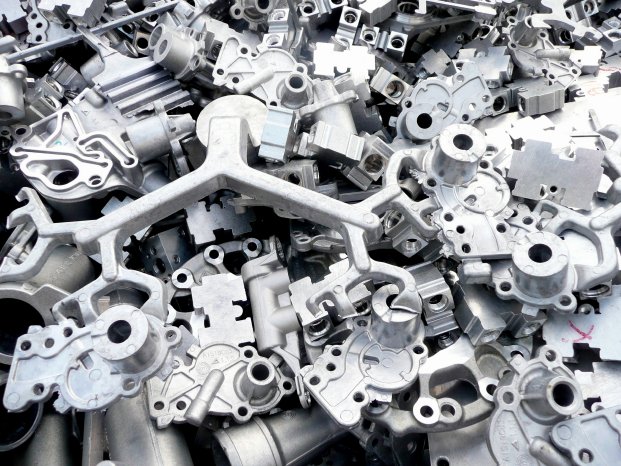

Even in modern production-optimized foundries, it is almost impossible to completely avoid faulty castings, casting residues or punching waste in the manufacturing process. Not only e-mobility, but also the general trend towards lightweight construction in the automotive sector has led to a sharp increase in the demand for aluminium in recent years, and the quantity of scrap material has increased accordingly. Whereas previously sprue systems and faulty castings were normally collected in containers, until a sufficient quantity was available for recycling and re-smelting, more efficient measures are now required. In view of rising raw material prices, it is also in the interest of foundries to return scrap material to the production process as quickly and efficiently as possible. In order to enable energy-efficient re- smelting, the parts must be shredded beforehand.

Demand-oriented shredding solutions

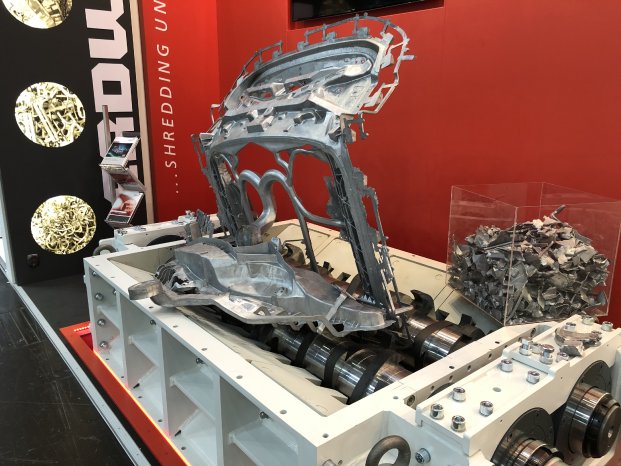

Faulty castings of gearbox housings or entire engine blocks as well as axle bearings, battery housings and sprue spiders are just some of the challenges that a reprocessing plant has to face. ERDWICH Zerkleinerungs-Systeme GmbH offers, with the RM1350/2 twin-shaft ripper and the M600/1 single- shaft shredder, solutions that meet the respective requirements. Both systems can be retrofitted into existing production lines to pick up and shred the rejects directly where they are produced. The handy sized aluminium parts can then be transported directly back to the furnace systems via conveyor belts or collected in containers. The volume of cast parts is reduced by 50 to 60 percent. This eliminates the need for space-consuming and expensive intermediate storage of the scrap material. In particular the RM 1350/2 is equipped to meet all challenges, thanks to its variable cutting unit size, with a width of 1,350 mm and a length of 1,500, 2,000 or 2,500 mm. The knives of the cutting unit are made of low-wear special steel and can be inserted individually to enable different cutter sequences depending on the material to be shredded. This method enables the knives to be prepared or sharpened as required without having to remove the entire shaft. Depending on the application, drive loads from 45 kW to 132 kW can be selected to achieve a throughput of 1.5 to 5 tonnes per hour. The machine control also allows alternating forward and reverse motion of the shafts to increase throughput for bulky parts. The specially developed PLC control, with automatic reversing and switch-off, protects the machine from damage caused by overload should bulky components jam in the ripper.

Integration into the production chain

For an optimal integration of the shredding plants into existing production lines, the experts from ERDWICH offer an on-site visit to get an overview of the spatial conditions. Based on this, a constructive solution is worked out which makes optimum use of the available space whilst providing for the necessary plant size. The machine is integrated into complete production lines as a fully automated solution in order to ensure that the shredded materials are returned to the production process as quickly as possible. The return of the metal parts is carried out either via conveyor belts or by collecting them in containers and are then melted down again. The shredding also means that the energy consumption of the melting furnaces can be reduced, as the small parts can be melted down more easily and quicker. The reprocessing of the scrap parts thus becomes the first production step in an energy-efficient and cost-saving production cycle.

At EUROGUSS 2020 in Nuremberg, ERDWICH will present both the M600/1 and a cutting unit of the RM 1350/2. Managing Director Harald Erdwich and his colleagues will be available for initial discussions and concrete enquiries in Hall 9, Stand 9-315.