Humans will continue to play an important role in industrial value creation in the future. However, manual work processes are extremely difficult to analyze. The company MotionMiners GmbH provides a solution to this problem.

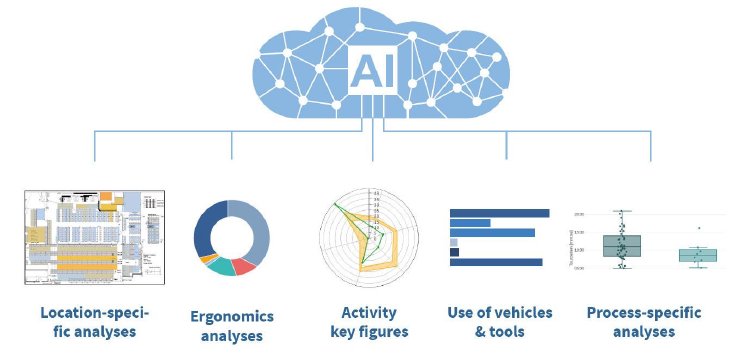

In order to record the various activities, the employees carry mobile sensors. The localization is done via beacons. After a few weeks of measurement, the data is analyzed with a highly specialized artificial intelligence. Individual activities and process steps are clearly displayed in an analysis dashboard. Thus, for example, walking, waiting or handling times can be analysed effectively. In addition to the efficiency of the work processes, knowledge about the physical workload of the employees can also be gained. These analyses help improve the work situation of employees, prevent work-related illnesses and keep experienced employees in the processes for longer.

The technology of the young company can be used in many ways, for example in logistics or production. Customers can carry out analysis on their own as well as make use of the consulting services of MotionMiners GmbH.

Highlights

- No integration into the operational IT necessary

- Holistic analysis of efficiency and ergonomics

- Time saving through automatic recording and analysis

- Complete anonymization of the collected employee data

Analysis examples

Heatmaps: Duration times per region and process step are uncovered. Routes are additionally (iteratively) visualized to uncover inefficiencies.

Process key figures and statistical evaluations: Each process step can be analyzed. Travel times, waiting times, the duration of clarification cases, benchmarking or outlier analyses are only some of the possibilities to identify problems and raise potentials

Analysis of ergonomics: The identification and reduction of ergonomic risks can decrease stress related illnesses and increase employee satisfaction.