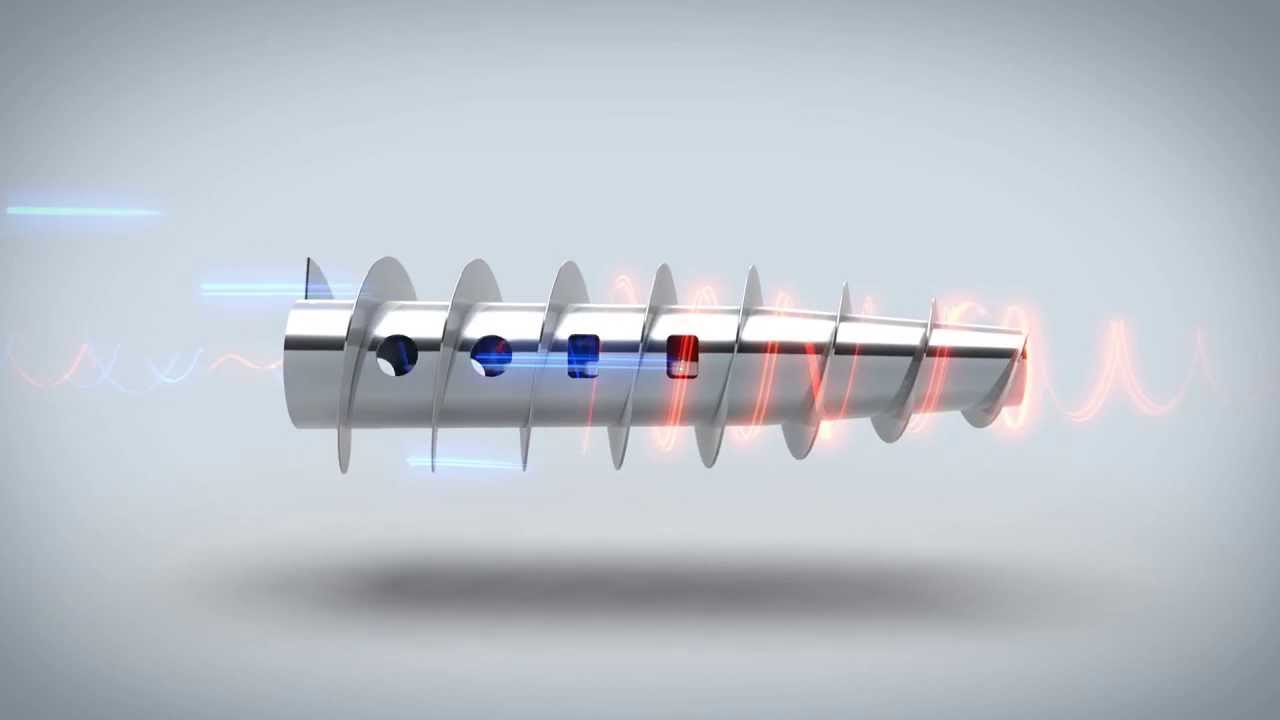

Over five decades, Flottweg has gathered rich knowledge of the area of sewage sludge thickening and dewatering. That know-how has now gone into a new generation of environmental centrifuges. The requirements for the C2E are just as high as for the big Flottweg Decanters. Among other things, the machine consists of a bowl of duplex steel, with all product-wetted components made of rust- and acid-resistant 1.4404 (3-6) stainless steel, high-quality wear protection with wear components that can be replaced on-site. No-compromise implementation of our latest discoveries for the bowl and scroll geometry, as well as high torque on the scroll and a high acceleration factor (g value) ensure the best possible separation results.

The C2E also has Flottweg's patented Simp Drive®. The Simp Drive® regulates the differential speed between the decanter bowl and the decanter scroll, depending on the scroll torque.

Customers can also optionally choose the Flottweg Recuvane® system. This system uses the targeted centrate removal for the recovery of rotational energy, supporting the main drive and further reducing energy costs. Savings of around 20 percent are possible thanks to Recuvane®.

Although the C2E, with a throughput of about 10 m³/h during sludge dewatering or 15 m³/h during sludge thickening, is dimensioned more for small communities, disposal costs still play a central role. The efficiency of the machine with respect to separation results reduces the overall lifetime costs to a minimum.