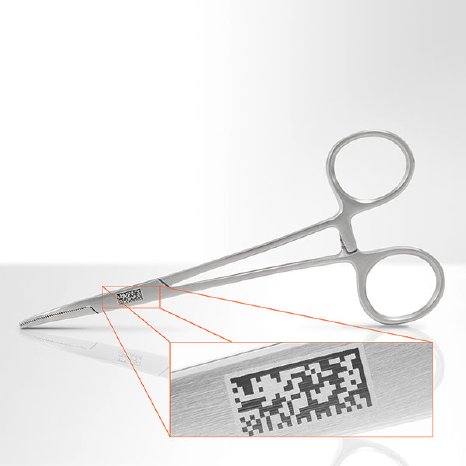

Innovative laser technology has become the preferred solution for marking medical devices as it enables medical device manufacturers to overcome marking challenges.

Particularly zero-defect laser marking plays an increasingly important role in manufacturing medical devices since the FDA (Food and Drug Administration) requires that, by 2016, every medical device in the USA contains a 2D code for traceability. The key to meeting the FDA identification requirements while reducing production costs, minimizing waste and improving product quality is a laser marking system combined with the software concept HELP (Holistic Enhanced Laser Process).

Apart from the marking of the medical product itself, HELP offers pre-mark verification prior to marking and post-mark validation right after marking. Particularly important for medical device manufacturers: During the unique post-mark verification process, the content of 1D and 2D codes (e.g. Datamatrix [ECC200] GS1 compliant and graded) can be directly read which is indispensable for compliance with the new Unique Device Identifier set by the FDA.

More information: www.fobalaser.com