The innovative VLG (volume light grid for logistics) volume measuring system from FRAMOS Imaging Systems enables three-dimensional measurement and volume of general cargo to be recorded in real time providing seamless automated integration and use of this key information in logistics processes.

The extensive application diversity of the VLG in a wide range of standard configurations enables, for example, verified receipt of goods including precise documentation and optimised utilisation of storage space and warehousing as well as automated processing and picking and constant quality control for the correct efficient deliveries.

The robust measuring technology based on transmitted light measures any objects across a wide range of industries regardless of their optical properties, such as the degree of reflection or transmission. In contrast to traditional laser incident light technologies, the VLG is also able to reliably measure transparent, matt-black or reflective objects – which is critical in areas such as retail or baggage logistics.

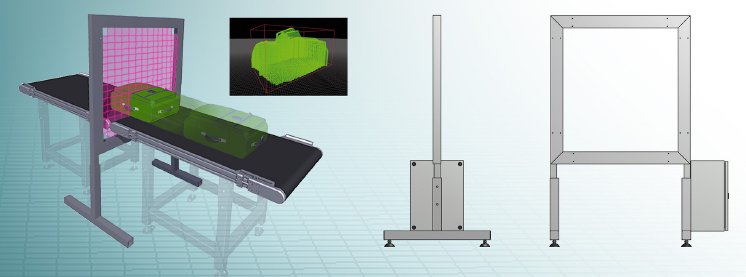

Plug & Play makes the VLG flexible and very easy to implement in all customer systems without the need for any configuration and offers an extremely attractive price-performance ratio. It is available in versions with measuring sizes between 50x50 cm and 3x3 m and with resolutions from 2.5 to 10 mm as well as customer-specific variants. Seamless integration into any conveyor system and the modular service-friendly construction with very short MTTR times makes the VLG the perfect cost-efficient solution for the robust, geometric measurement of all kinds of goods.

Dr. Simon Che’Rose, Head of Engineering at FRAMOS Imaging Systems, explains the advantages of the volume light grid for logistics: “The VLG, unlike other commercially available systems, is able to cope with a wide range of objects and produces error-free measurements with a high degree of analytical reliability. Our many years of know-how from the image processing and project business guarantees the high quality of the software. We are raising logistics to a new level through automation processes including sorting and orientation tasks as well as quality assurance measures such as verification and completeness inspection.” The VLG delivers immense value-creation and cost advantages in the supply chain and supports companies with the efficient automation of logistics. FRAMOS Imaging Systems already operates very successful test projects on the customer side and will present the VLG to the general public at LogiMAT 2014 in Stuttgart (Hall 6, Booth 474).

Abstract:

How does a volume light grid work?

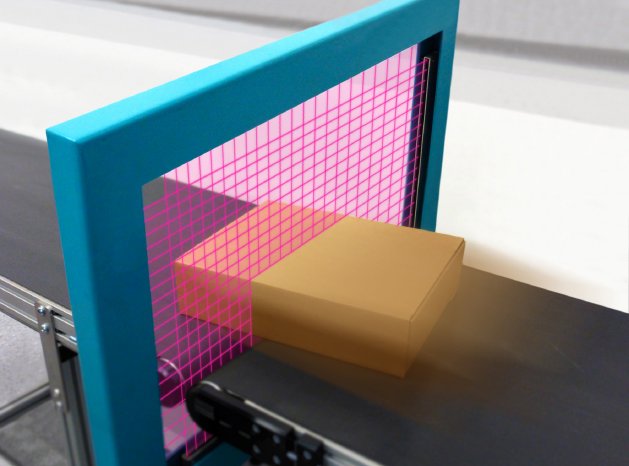

The volume light grid – or light curtain – consists of opposing LED strips that make up the transmitter and receiver. The transmitter LEDs, which are arranged at regular intervals, emit light beams that strike photoelectric diodes in the receiver strip. An adjustable switch-point identifies whether and in what intensity the emitted light arrives on the opposite side. When a number of diodes are blocked by an object, this condition can be read out and used to generate contour information that enables a virtual reconstruction of the object. The vertical and horizontal arrangement of the strips enables height and width measurements, while additional movement information produces a three-dimensional image with lengthwise measurement. In this way, the volume, position and orientation of the so-called bounding box on the conveyor system is illustrated.