With a broad range of camera models providing different technical features the imaging market for cameras and camera systems is pretty diversified. Based on the manufacturers data sheet with different, not comparable performance indicators or a lack of vital information it’s a hard job for imaging engineers to evaluate and to choose the suitable camera or sensor for a given vision application.

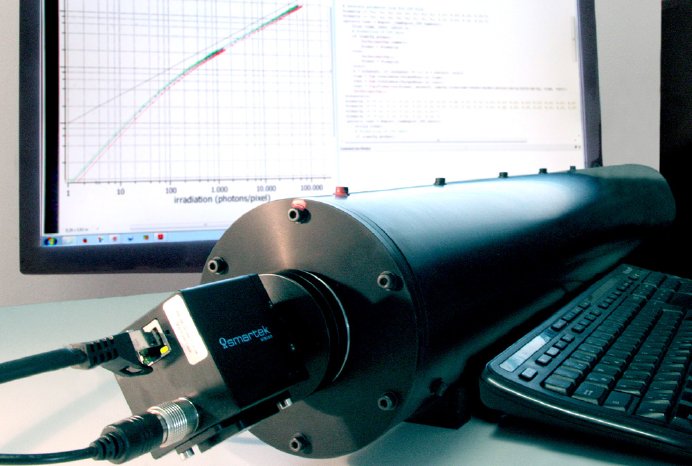

The EMVA 1288 Standard creates transparency by defining reliable, exact measurement procedures, and makes the comparison of cameras and image sensors much easier. The consistent test provides an easy to compare overview about the sensor quality and presetting, about the downstream electronics, the functional interaction and so about the holistic optical and electronic quality of the camera with inferences to single components.

Stefan Waizmann, Head of Product Management at FRAMOS, explains: “In industrial imaging the EMVA 1288 test reporting is on its way to become increasingly important and is requested by a significant number of customers. It is the only manufacturer independent standard to characterize cameras in their entirety. The EMVA certificate will be available for all our distributed camera brands and upon request for all other types of cameras as additional service.”

With the EMVA 1288 Standard the dynamic range, sensitivity and noise over flatness are measurable. How the color production quality and sensitivity to light of the camera is to rate and how is the real resolution of the camera system together with the lens? All presetting getting transparent with EMVA 1288 and enable the customer to assess different features like dark current noise or linearity for a more appropriate camera selection.