In high precision applications, for example manufacturing assembly lines, robotics vision systems and production surveillance imaging engineers need high quality lenses for large optical sensor formats and small pixel sizes to avoid dark edges while using the whole resolution provided by the imaging sensor.

Stephanie Zahner, Line Manager at Kowa’s distributor FRAMOS, points to the industries already benefiting from the increased lens stability: “Where subpixel accurate measurement is needed, like in 3D measurement systems for body working and prototyping or stereoscopy systems, greater precision and stable results are achievable. Same for all applications where the optical axis has to be stable independently from the lens’ position and in harsh environments like printing machines, railway inspection and other choppy constructions.”

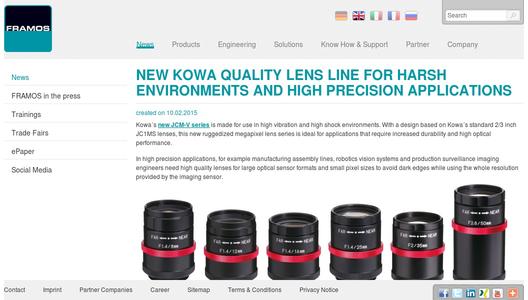

Kowa's JCM-V series was designed for megapixel applications requiring a sensor size of 2/3” (Ø 11mm) or smaller. Another key design feature of this series is, that all internal glass elements of Kowa’s ruggedized megapixel lenses are glued, allowing for a highly stable optical axis and perfect adjustment. The unique mechanical design guards against strong vibration and shock while a two-way reversible nut is utilised to tightly lock the focus adjustment ring in place. Instead of mechanical iris diaphragms with moving blades, attachable interchangeable iris plates are used to select the F-stop.

With an acceleration durability of up to 5G and a vibration frequency from 10 to 500Hz for a maximum of 180 minutes, the JCM-V series is the new standard for anti-vibration and high-shock lenses. Available with a focal length of 8, 12, 16, 25, 35 and 50mm and a center/corner resolution of 100/80 lp/mm using C-Mount, the lenses can have customized features to fit application requirements.