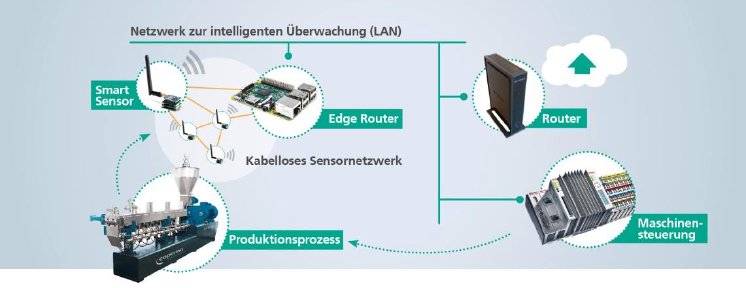

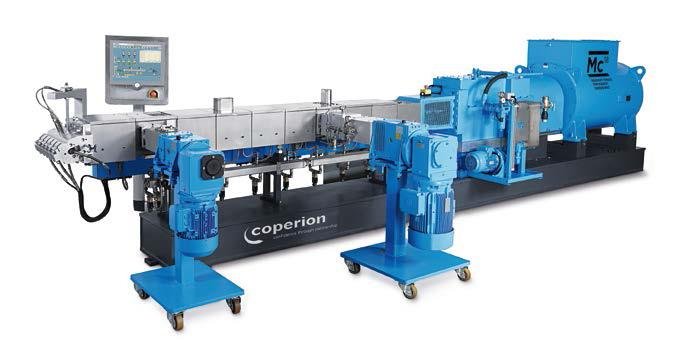

"Cyber-physical systems connect and coordinate. This creates completely new opportunities for applications, but it also represents new challenges for developers, who will have to find a way to work with this increased complexity and heterogeneity“, explains Dr. Christian Beinert, head of Polymer Processing and Component Design at Fraunhofer LBF. Based on the monitoring system developed at LBF, support can be offered to the companies in the field of condition monitoring or predicted maintenance. In collaboration with the machine manufacturers and operators of the machines and manufacturing plants the experts of Fraunhofer LBF can configure this flexible modular and customizable system to match the customers’ specific needs. “By combining existing data from the machine control system with selected, additionally recorded sensor data, we can detect unfavorable operating conditions or material fluctuations, and thus minimize faulty batches or machine failures“, explains Dr. Beinert.

The Darmstadt researchers furthermore are implementing signal pre-processing, which means that data measurements can be reduced already within sensor nodes. Through the use of a multifunctional gateway, the pre-evaluated sensor data will be collected, processed and the information will be made available in a data pool. The data for identification of damages on the other hand will be compared with established data collectives.