Leistungszentrum Elektroniksysteme (LZE) is a joint initiative of the Fraunhofer-Gesellschaft, its two Institutes Fraunhofer IIS and Fraunhofer IISB, and Friedrich-Alexander University Erlangen-Nürnberg (FAU), in addition to other non-university research institutes and various industry partners such as Siemens. It grew out of many years of intense cooperation between the two Fraunhofer Institutes in Erlangen and FAU. There is a unique concentration of electronic systems research activities and industries based in the Nuremberg-Erlangen region. Research excellence and joint planning have created the foundation for a comprehensive, long-term strategic partnership between Fraunhofer, FAU and the electronics industry.

The research work of LZE addresses the development of complex electronic systems through a novel engineering platform that serves as a methods-based framework for generating, distributing, and applying research results. This includes broad competencies in power electronics, ICT, sensor technology, semiconductors, energy management, and materials science. LZE focusses on two major areas of technology: power electronic systems for, e.g., energy supply and mobility, and low-power electronics for sports and health applications (“wearables”), Industry 4.0, and the Internet of Things. The partners not only build and continually develop the working relationship through processes such as joint roadmapping, they also jointly create new cooperation models. LZE structures its research activities to ensure that the results lead to the development of successful and innovative products for the industry partners.

The research partners of LZE form an outstanding concentration of expertise: FAU comprises a Faculty of Engineering with 10.000 students. In addition, as FAU covers the entire spectrum of academic disciplines, there are large competencies in topics that accompany the development of electronic systems, such as economics or social aspects. With about 1.000 engineers in two Fraunhofer Institutes, Erlangen is the strongest Fraunhofer location for electronic systems. This is supplemented by the research labs of other non-university institutes and leading industrial companies in the region.

LZE launched its 30-month pilot phase in January 2015, including four pilot projects which address industry-relevant topics from power electronics to low-power electronics and demonstrate the wide spectrum and great capability of the LZE consortium. The latest R&D results of the pilot projects are presented at SEMICON Europa.

DC backbone with power-to-gas coupling

The rising share of renewable and decentralized energy production is putting new strains on today's electricity distribution systems, a problem that manifests itself in local oversupplies and undersupplies of energy, in addition to heavy fluctuations. The combination of new intelligent grid structures and electrochemical energy storage creates an opportunity to absorb this effect in local microgrids and thus take the load off the mains. The LZE project combines intelligent DC microgrids in buildings with an optimized combination of electrical and chemical energy storages. This comprises highly efficient lithium-ion battery storages for compensation of short-term fluctuations but also storages based on liquid organic hydrogen carriers (LOHC) for large-scale and long-term, seasonal storage. The size of the LOHC tank, which can be easily expanded, defines the storage capacity. At LZE, a prototype setup is being implemented with a 1 MWh LOHC storage in a shipping container, aiming at 30 kW charge/discharge power and a self-discharge of less than 1% per month.

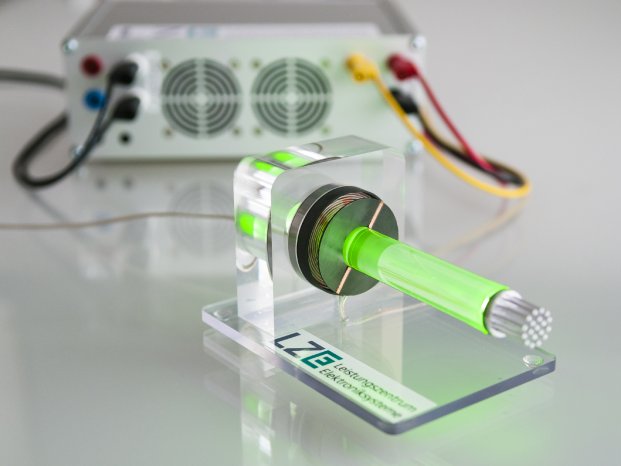

Wireless power and data transfer in systems with fast-moving parts

Many applications require transferring power and data in moving systems. Examples include highly-automated autonomous production systems such as those envisioned for Industry 4.0 and robotic systems in which power and information have to be transmitted to the joints. In most cases, this requires the use of slip rings or flexible cables that are subject to wear and tear. The wireless technology is demonstrated at the example of a standard ball bearing with an inner and outer diameter of 20 mm and 52 mm, respectively. Despite the reduced axial installation space of 7 mm, a power of 20 W can be transferred to the rotating part due to high switching frequencies up to 1 MHz. The integrated bidirectional data transmission features a speed of 400 kBit/s for drive controls or sensors, which will be increased throughout the project.

Low-power electronics in sports and fitness applications

The project combines the Fraunhofer Technologies FitnessSHIRT and RedFIR to gather vital and position data from athletes during physical activity. The FitnessSHIRT is equipped with two textile electrodes to derive a single channel ECG together with a respiratory band to derive the respiratory rate. These vital data are pre-processed on an ARM processor and sent via Bluetooth to a tablet or mobile phone, where innovative algorithms analyze the data. Simultaneously, the RedFIR system, a radio-based tracking system, gathers position data with an accuracy of centimeters and is able to track athlete movements up to 40 km/h and ball movements, e.g., in football applications, up to 150 km/h. Additional energy harvesting systems will provide power generated from temperature differences and vibrations.

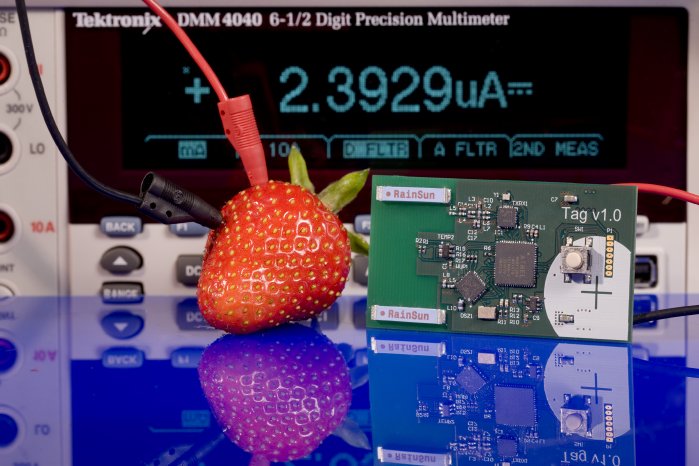

Energy-independent asset tracking system for logistics applications

Within this project, an ultra-low-power indoor-localization and tracking system for logistic applications is being implemented. A fundamental basis is an integrated ultra-low-power UHF wake-up receiver for the SRD bands at 433 MHz, 868 MHz, and 2.4 GHz with an active current consumption of 2 µA at 2.5 V supply for each frequency band. The indoor localization takes place at each object and not only in a central unit. Battery-driven wireless beacons placed at each landmark transmit position data, e.g., at 433 MHz every 60 seconds. Thus, hundreds of objects can detect their current position on their own without interaction with a central unit and can store the information as a local history log. Moreover, batteryless operation is performed using two energy harvesting devices: a thermoelectric and a piezoelectric generator. By this, both local temperature differences of about 1 Kelvin at the wireless module and small mechanical impulses are used to supply the wake-up receiver with electrical power.

LZE is supported by the Bavarian Ministry of Economic Affairs and Media, Energy and Technology.

At SEMICON Europa 2015, LZE can be found at booth 2092 (Science Park, Hall 2), as a member of the joint booth of the Fraunhofer Group for Microelectronics. The Fraunhofer Group for Microelectronics with 16 member institutes is a leading European R&D service provider for Smart Systems.

More information can be found on the LZE website www.lze.bayern.